Super-Trex® Ultra-Gard™ Portable Cord

Super-Trex® Ultra-Gard™ Portable Cord is highly flexible and is rated for usage in harsh industrial environments with excellent resistance to impact, cutting, abrasion, oils, and most industrial chemicals.

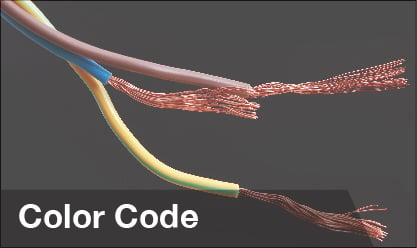

This SOOW portable cord features tinned, extra-flex stranded copper conductors and live-flex insulation with no-wick reinforced fillers and a 100% fabric serve. The security yellow TSE jacket provides excellent protection against pulling and twisting and allows for extreme all-weather flexibility.