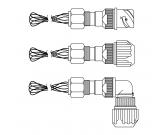

Mil-Spec MIL-C-5015 Assemblies

TPC offers a wide range of circular connector assemblies designed and manufactured to MIL-C-5015 standards. Originally developed by the armed services for use in severe aeronautical and tactical service applications, military connectors are short in length and feature a low-profile design.

TPC’s version also offers a back shell designed to increase the life span of the cable. TPC military connector assemblies are an ideal choice for harsh automotive, metal, wood, food & beverage, marine, and other industrial applications where a rugged, threaded connector is required. The combination of TPC’s high-performance cable, the proven reliability of the MIL-C-5015 connector, and the flex/strain relief of our back shell make for an unbeatable system.

Our assembly options include 180 contact layouts ranging from 1 to 65 positions and up to 150 amps per contact. Our layouts also allow for the mixing of power and signal contacts, power only and signal only.