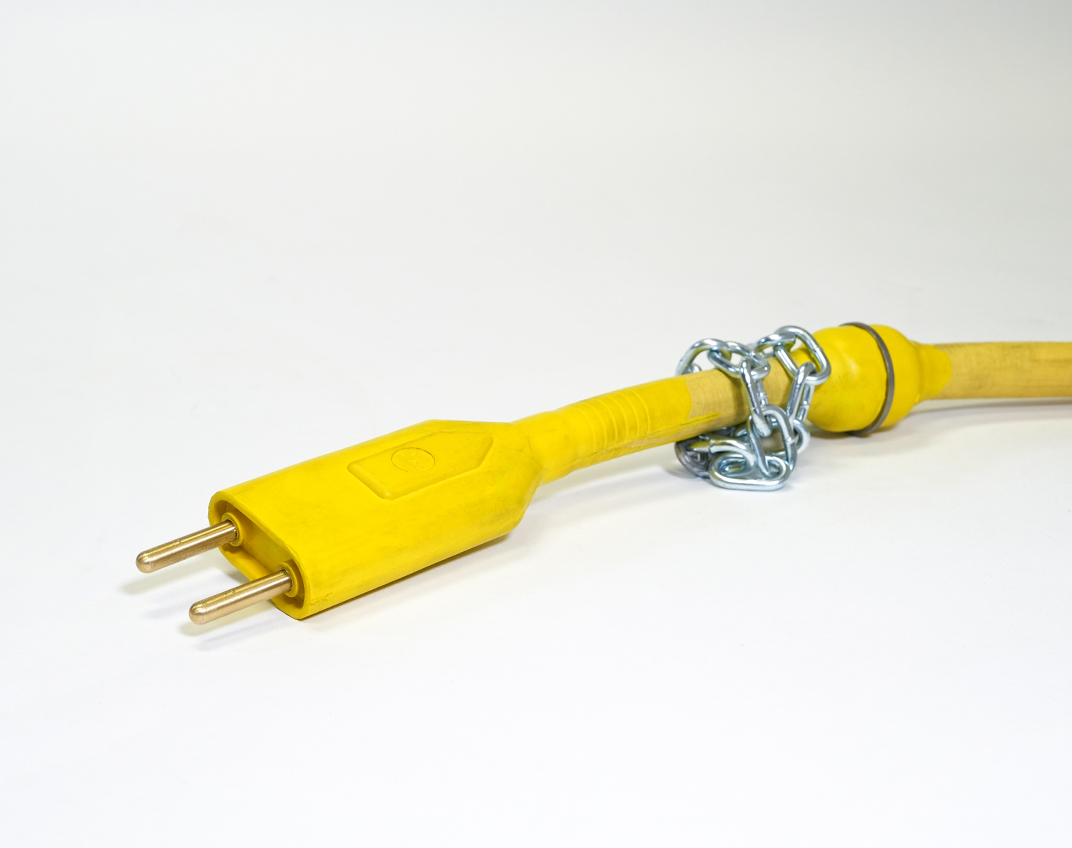

Oval Power Assemblies

The rugged Oval Power Assembly is built with our Super-Trex® Type W Power Cable which provides a superior first line of defense against cutting, tearing, abrasion, and impact.

The standard pin and sleeve configuration is interchangeable with most standard connectors. The rubber collar molded at the base of the male pins forms a "cork seal" connection when plugged into a matching unit from TPC Wire & Cable. This seal reduces carbon arcing and insures ingress protection against dust and liquids.