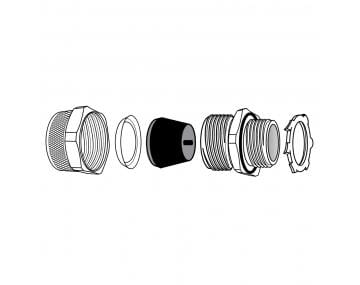

Grip-Seals® Aluminum Cable Glands

Each Grip-Seals® Aluminum Cable Gland package includes the cable gland body, O-ring and locking nut. Our aluminum compression bushing and threaded body is resistant to corrosion and weathering, and has a maximum operating temperature of 121°C. The nickel-plated friction ring provides a uniform compression for a proper environmental seal against dust, moisture and chemicals. Our Grip-Seals® Aluminum Cable Gland is available in straight and 90 degree configurations.

.jpg)