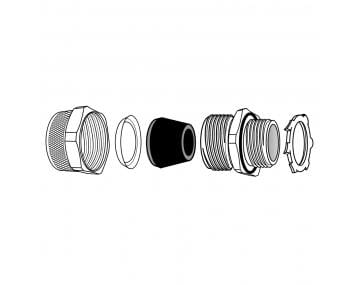

Grip-Seals® Heat & Chemically Resistant Cable Glands

Grip-Seals® Heat & Chemically Resistant Cable Glands operate up to 150°C, resist impact and corrosion, and provide exceptional gripping strength. It's an ideal accessory for use with our Chem-Gard® product line.

.jpg?width=360&height=285&name=nylon-straight-grip-seal_1%20(1).jpg)

.jpg)