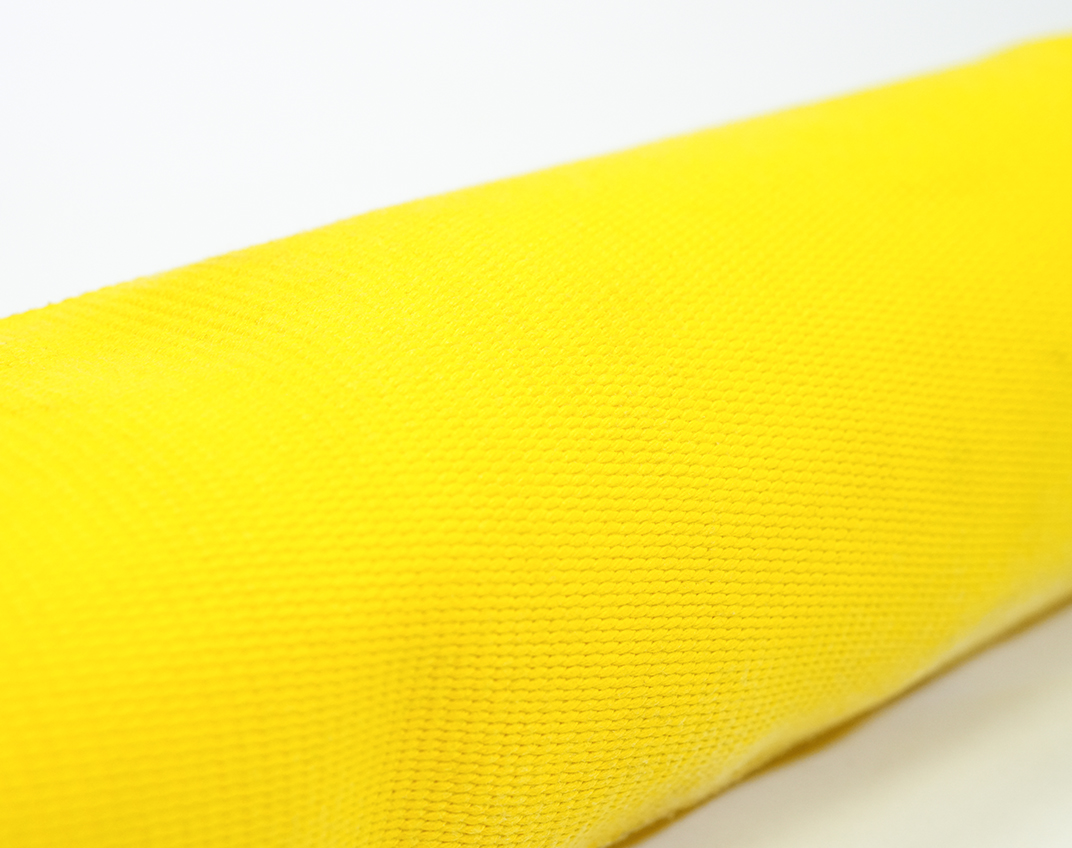

Abrasion Resistant Ultra-Sleeve

Abrasion Resistant Ultra-Sleeve is constructed with an extra thick nylon/polyester blend fiber. Ultra-Sleeve offers superior protection against tearing and abrasion adding greater protection to your electrical cables, water lines, hydraulic hoses, air lines and other critical areas. It offers heat resistance up to 66°C / 150°F. Also available with hook and loop closure, zipper closure or both hook and loop and zipper closure. Yellow color.