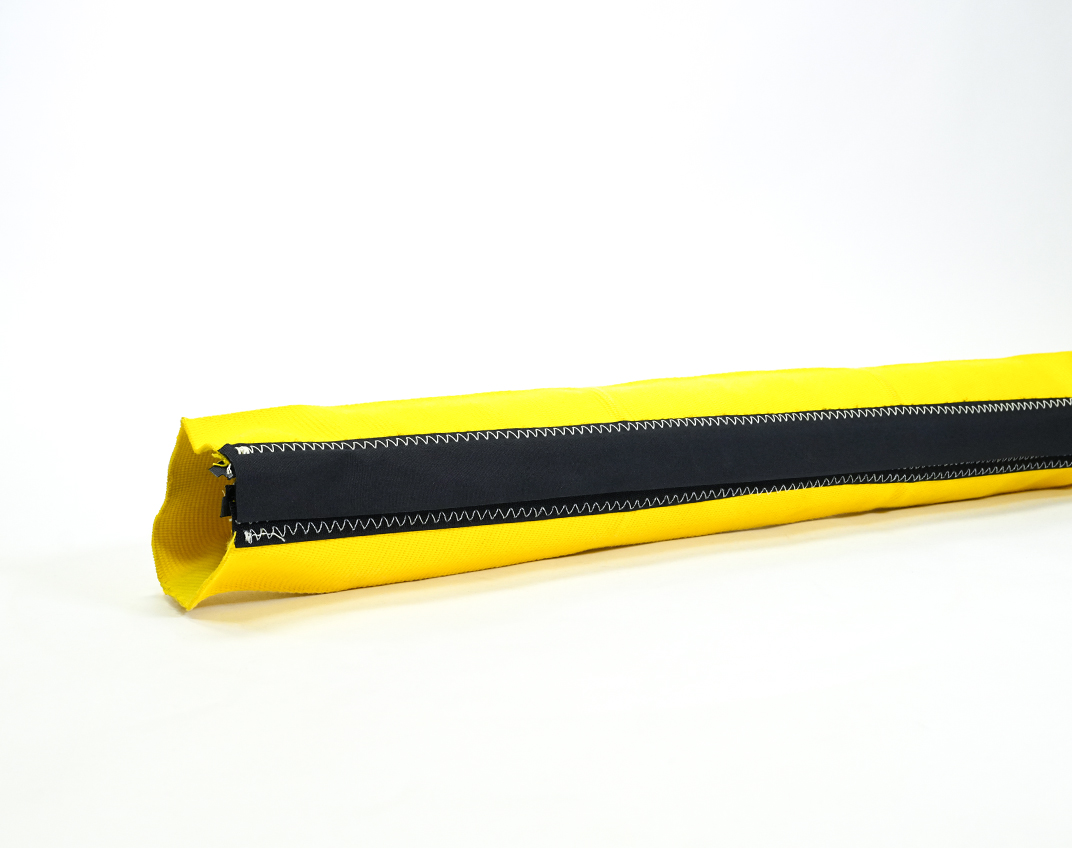

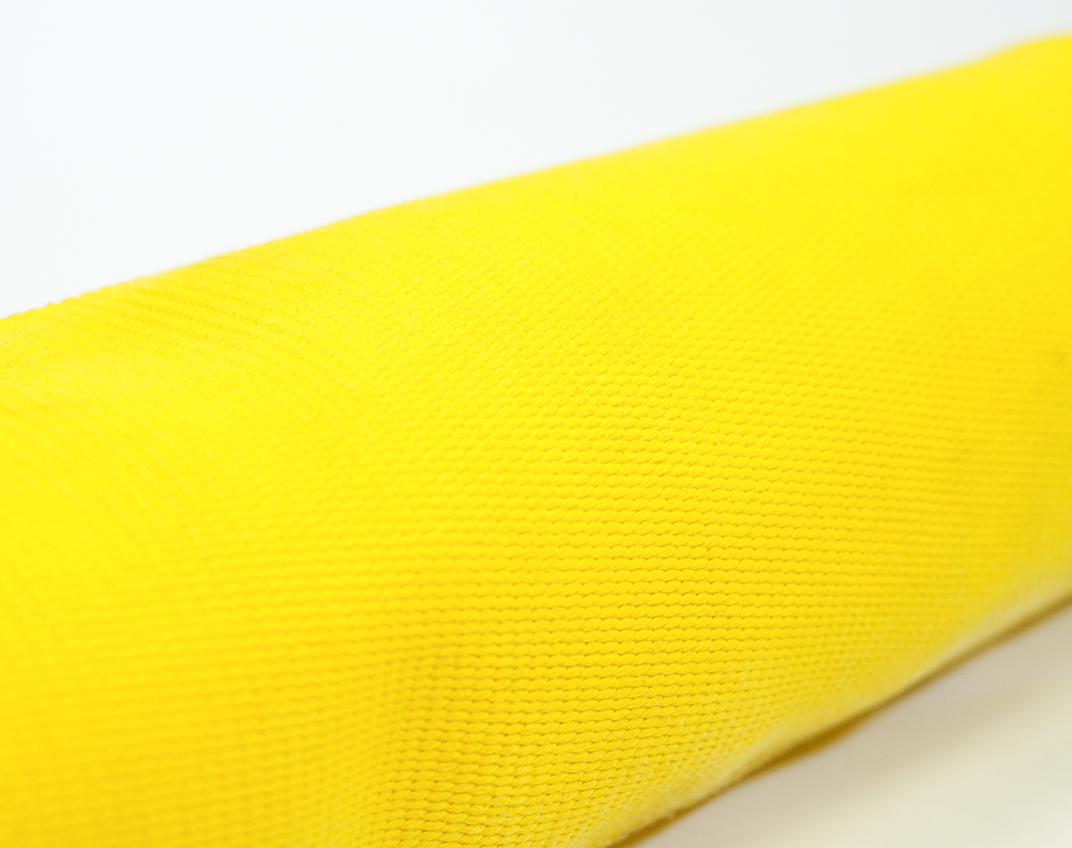

Abrasion Resistant Ultra-Sleeve with Closures

Abrasion Resistant Ultra-Sleeve with Closures offers a quick and easy way to install protective sleeving. Choose from hook and loop closure, zipper closure or both hook and loop and zipper closure. Ultra-Sleeve offers superior protection against tearing and abrasion, adding greater protection to your electrical cables, water lines, hydraulic hoses, air lines and other critical areas. It offers heat resistance up to 66C / 150°F. Available in 1-1/2", 3-1/2" and 5-1/4" inner diameter. Multiple lengths and closure options make this a highly flexible option.