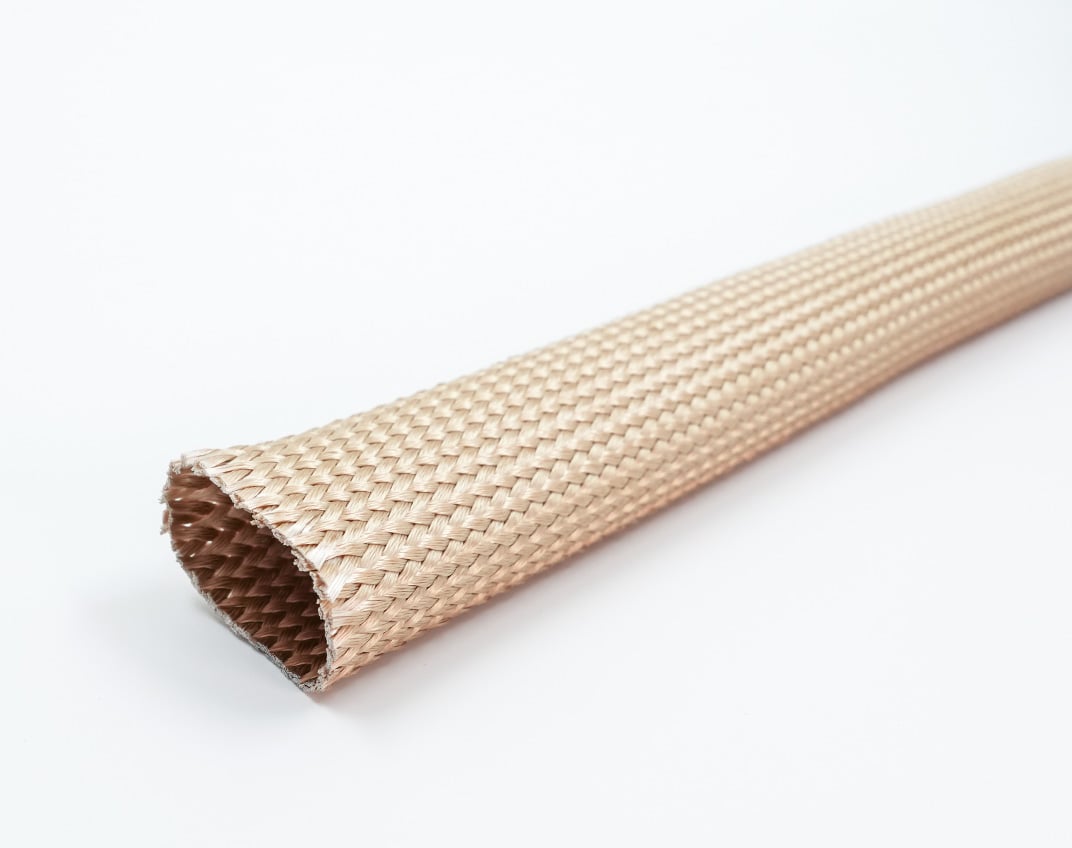

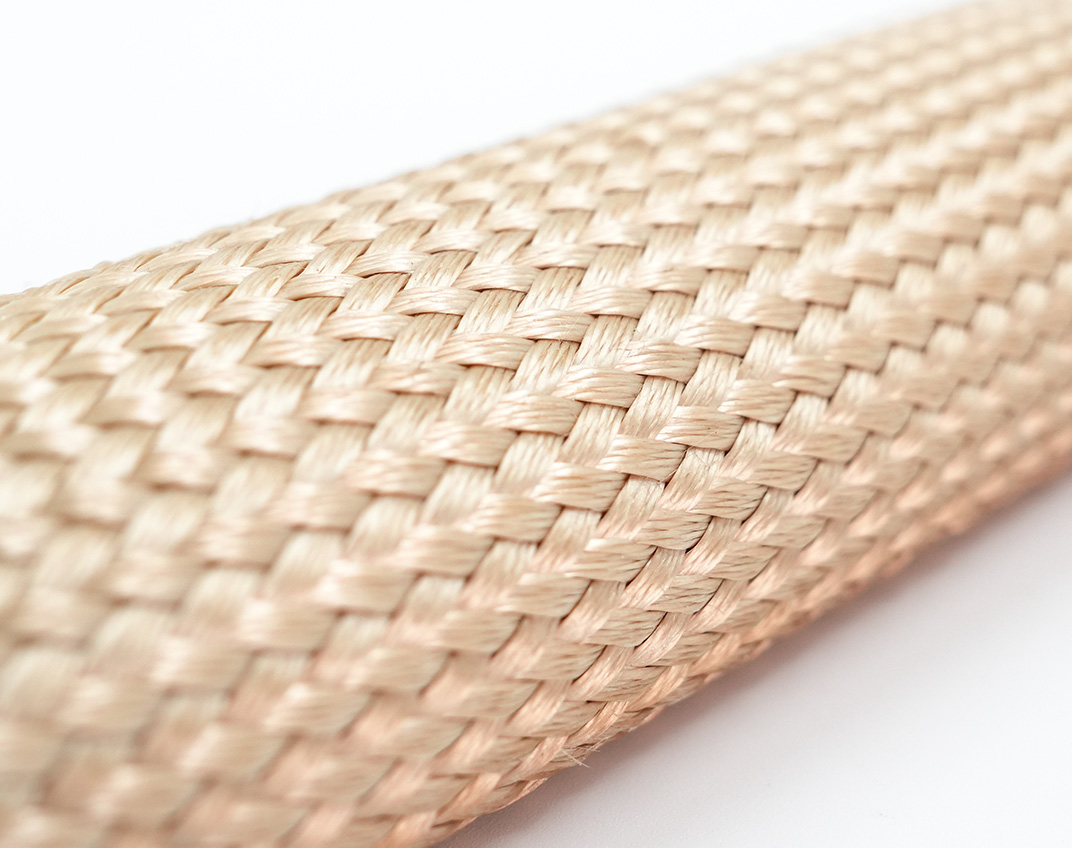

Thermo-Trex® Fiberglass Ultra-Sleeve-High Temperature Sleeving

Fiberglass Ultra-Sleeve High-Temperature Sleeving is a protective sleeve that is ideal for those areas where your cable runs through a particularly harsh environment of flash heat or flame, chemical or mechanical abuse. The Fiberglass Ultra-Sleeve offers great heat resistance up to 538°C. Available in inner diameters from ¼” to 2-1/2” to fit cable ranges from 1/8” to 4”.