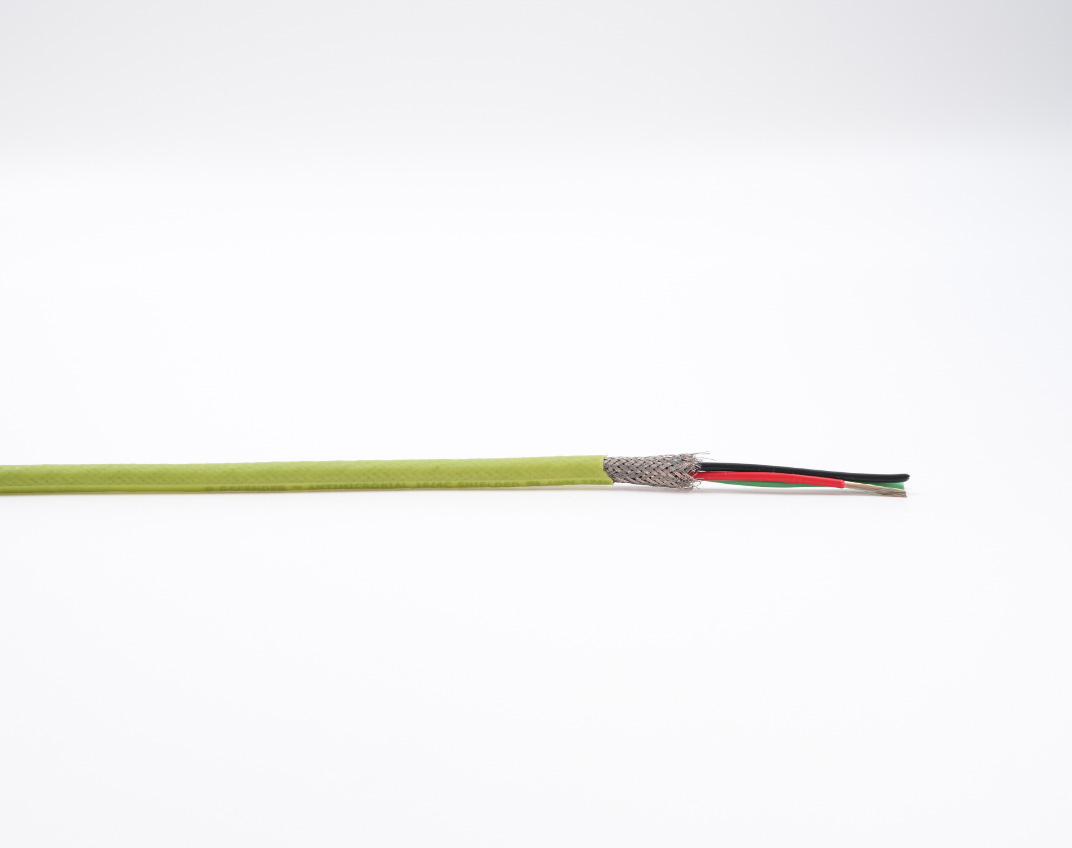

Chem-Gard® 150 Cable with Defender® Technology

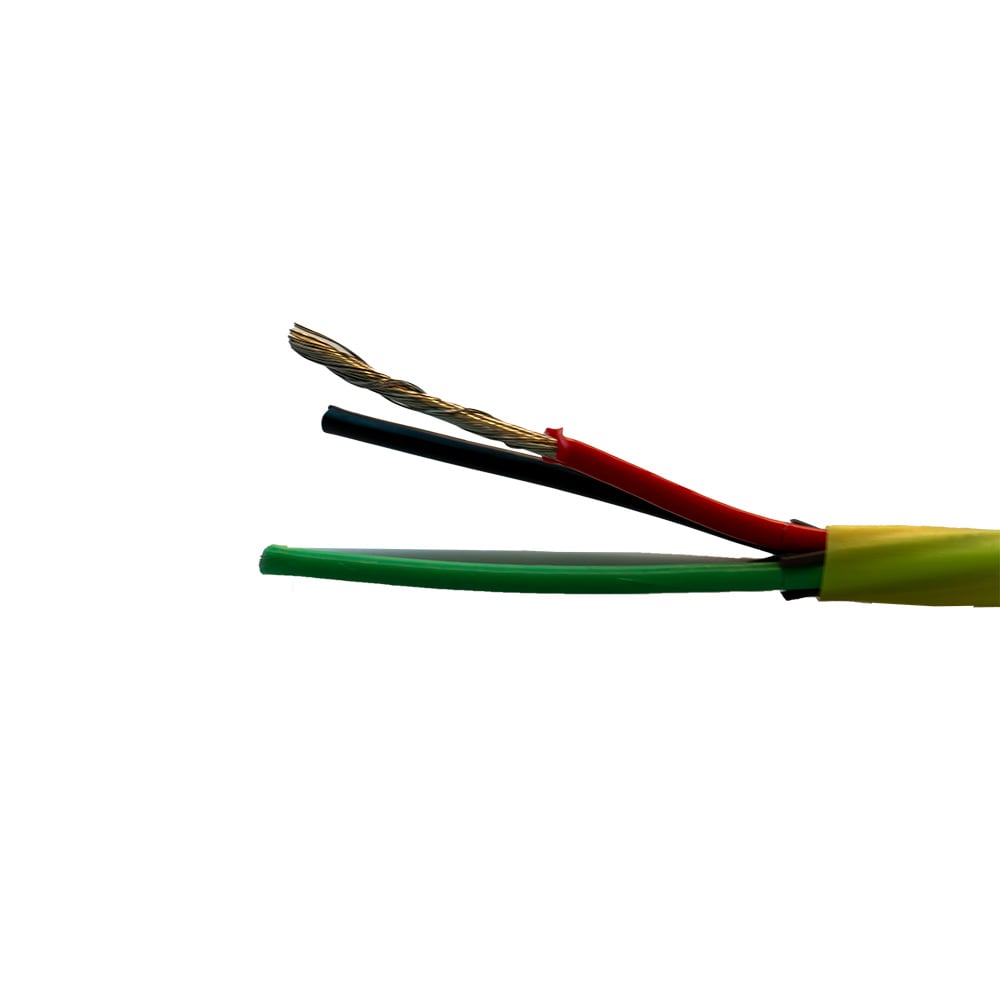

Chem-Gard® 150 Cable with Defender® Technology is a high-temperature and chemical-resistant cable for control and instrumentation applications that can withstand a maximum conductor temperature of 150°C / 300°F.

This control and instrumentation cable prevents the growth of 99% of bacteria, fungus and mold growth on the cable jacket. Silver ion-based additives provide built-in long-lasting protection for the life of the cable providing a solution for high standards in environments where cleanliness is crucial.