Trex-Onics® Reduced Diameter Control Cable

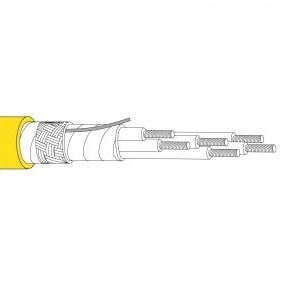

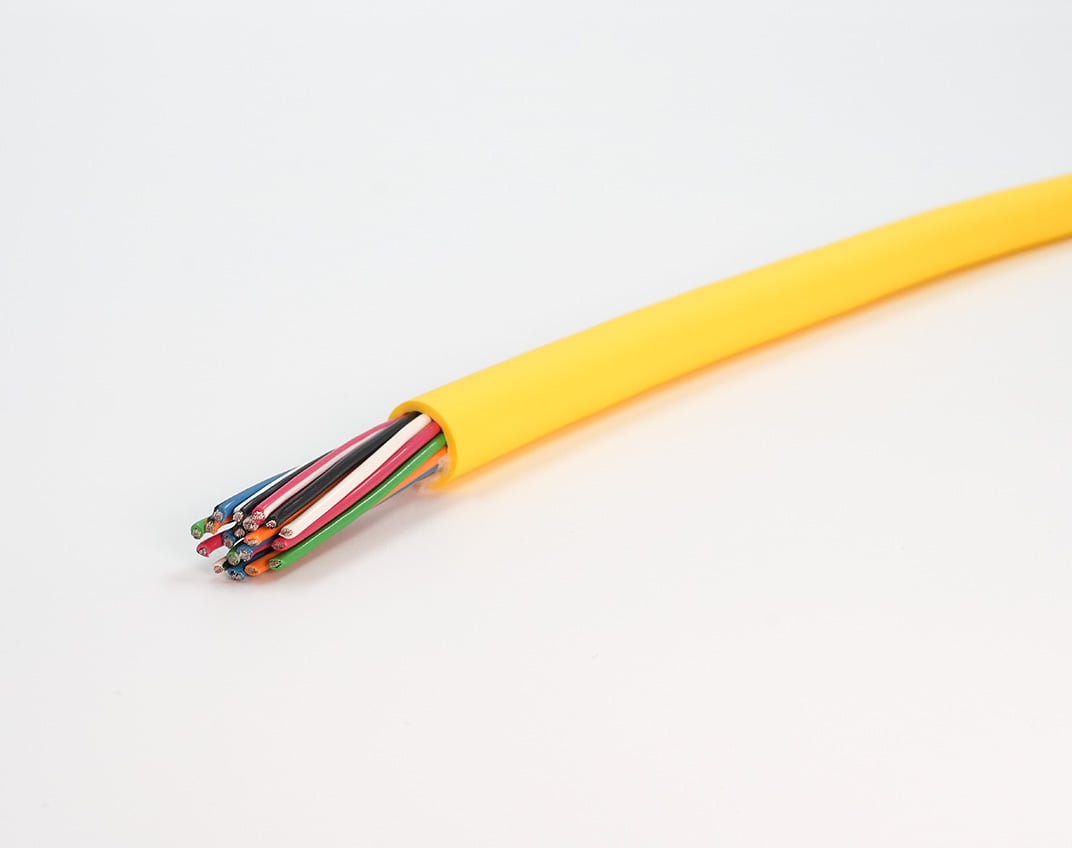

Trex-Onics® Reduced Diameter Control Cable is a multi-conductor unshielded control cable designed for industrial applications that require continuous flexing.

This control and instrumentation cable features a high strand count, TPE insulation, and a security yellow TPE jacket that provides excellent protection against abrasion, tearing, oil, and most chemicals.

.jpg)