Trex-Onics® HighFlex Encoder Cable

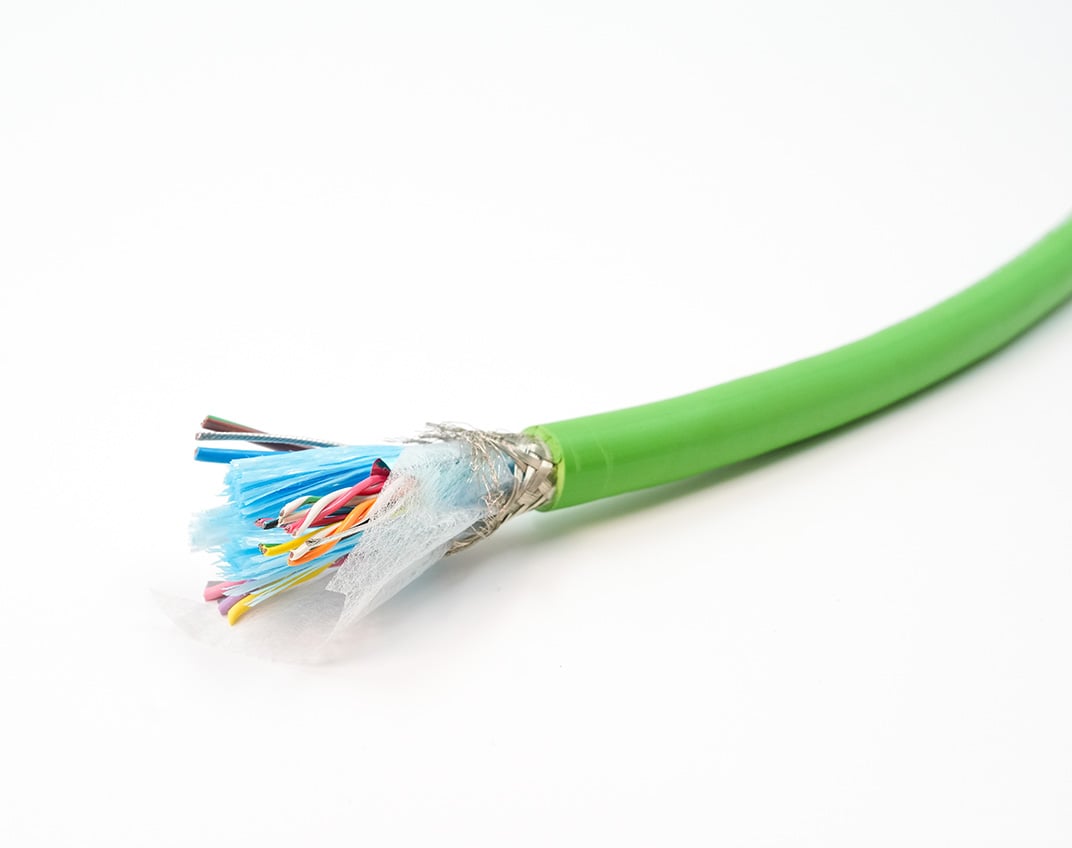

Trex-Onics® High-Flex Encoder Cable is built to withstand the harsh industrial environments in which many motors operate. This single-cable solution combines power conductors with signal pairs as well as the data element of dedicated encoder cables. The combination of multiple roles into a single-cable solution greatly simplifies inventory management, installation, and maintenance.

This composite cable features finely stranded tinned copper conductors that extend conductor life in dynamic applications. The oil-resistant insulation system offers high dielectric, tensile, and mechanical properties.

.jpg)