| 68412 |

24 AWG |

12 |

12 |

19/36 |

5 |

26 AWG |

26 AWG |

0.6 |

215 |

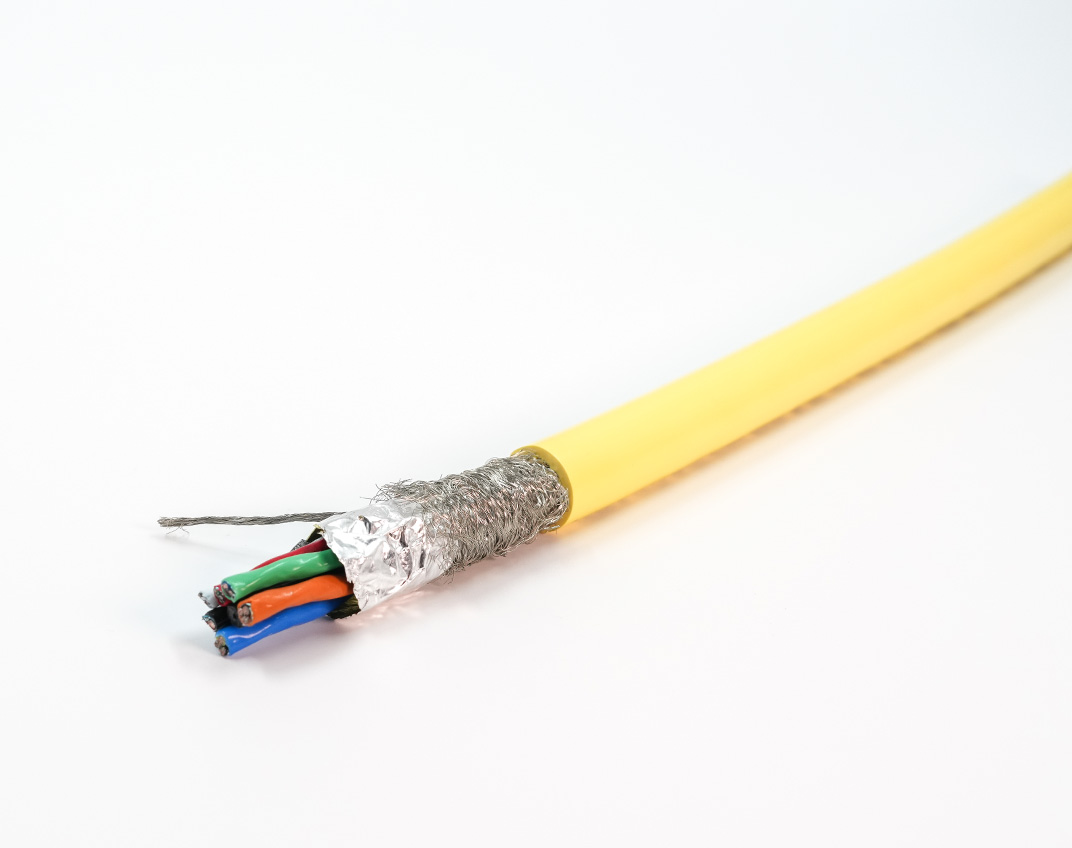

Overall Shielded, Individually Shielded Pairs |

| 68409 |

24 AWG |

9 |

9 |

19/36 |

5 |

26 AWG |

26 AWG |

0.57 |

160 |

Overall Shielded, Individually Shielded Pairs |

| 68406 |

24 AWG |

6 |

6 |

19/36 |

7 |

26 AWG |

26 AWG |

0.47 |

126 |

Overall Shielded, Individually Shielded Pairs |

| 68404 |

24 AWG |

4 |

4 |

19/36 |

7 |

26 AWG |

26 AWG |

0.39 |

86 |

Overall Shielded, Individually Shielded Pairs |

| 68403 |

24 AWG |

3 |

3 |

19/36 |

7 |

26 AWG |

26 AWG |

0.36 |

80 |

Overall Shielded, Individually Shielded Pairs |

| 68518 |

20 AWG |

18 |

18 |

19/32 |

6 |

22 AWG |

22 AWG |

0.85 |

540 |

Overall Shielded, Individually Shielded Pairs |

| 68512 |

20 AWG |

12 |

12 |

19/32 |

6 |

22 AWG |

22 AWG |

0.73 |

264 |

Overall Shielded, Individually Shielded Pairs |

| 68509 |

20 AWG |

9 |

9 |

19/32 |

7 |

22 AWG |

22 AWG |

0.72 |

247 |

Overall Shielded, Individually Shielded Pairs |

| 68506 |

20 AWG |

6 |

6 |

19/32 |

7 |

22 AWG |

22 AWG |

0.57 |

161 |

Overall Shielded, Individually Shielded Pairs |

| 68504 |

20 AWG |

4 |

4 |

19/32 |

9 |

22 AWG |

22 AWG |

0.48 |

118 |

Overall Shielded, Individually Shielded Pairs |

| 68503 |

20 AWG |

3 |

3 |

19/32 |

11 |

22 AWG |

22 AWG |

0.43 |

92 |

Overall Shielded, Individually Shielded Pairs |

| 68502 |

20 AWG |

2 |

2 |

19/32 |

13 |

22 AWG |

22 AWG |

0.41 |

74 |

Overall Shielded, Individually Shielded Pairs |

| 68312 |

18 AWG |

12 |

12 |

19/30 |

6 |

20 AWG |

20 AWG |

0.84 |

405 |

Overall Shielded, Individually Shielded Pairs |

| 68309 |

18 AWG |

9 |

9 |

19/30 |

7 |

20 AWG |

20 AWG |

0.79 |

320 |

Overall Shielded, Individually Shielded Pairs |

| 68306 |

18 AWG |

6 |

6 |

19/30 |

7 |

20 AWG |

20 AWG |

0.65 |

245 |

Overall Shielded, Individually Shielded Pairs |

| 68304 |

18 AWG |

4 |

4 |

19/30 |

9 |

20 AWG |

20 AWG |

0.54 |

163 |

Overall Shielded, Individually Shielded Pairs |

| 68303 |

18 AWG |

3 |

3 |

19/30 |

11 |

20 AWG |

20 AWG |

0.49 |

142 |

Overall Shielded, Individually Shielded Pairs |

| 68302 |

18 AWG |

2 |

2 |

19/30 |

14 |

20 AWG |

20 AWG |

0.44 |

110 |

Overall Shielded, Individually Shielded Pairs |

| 68204 |

16 AWG |

4 |

4 |

19/29 |

12 |

20 AWG |

26 AWG |

0.545 |

196 |

Overall Shielded, Individually Shielded Pairs |

| 68203 |

16 AWG |

3 |

3 |

19/29 |

14 |

20 AWG |

20 AWG |

0.49 |

158 |

Overall Shielded, Individually Shielded Pairs |

| 68202 |

16 AWG |

2 |

2 |

19/29 |

14 |

20 AWG |

20 AWG |

0.465 |

136 |

Overall Shielded, Individually Shielded Pairs |

| 68201 |

16 AWG |

1 |

1 |

19/29 |

18 |

20 AWG |

20 AWG |

0.285 |

65 |

Overall Shielded, Individually Shielded Pairs |