Thermo-Trex® 2800 Cable

Thermo-Trex® 2800 is a high-temperature resistant cable for power and control applications that can withstand a maximum conductor temperature of 537°C / 1000°F.

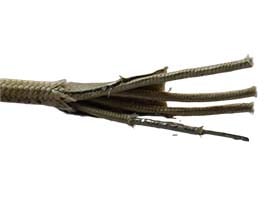

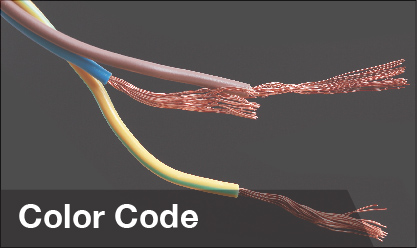

This flexible control and instrumentation cable features finely stranded, nickel-plated copper conductors and a specially woven glass-braid jacket impregnated with abrasion-resistant finishing compounds.

.jpg)