Thermo-Trex® Soaking Pit Cable

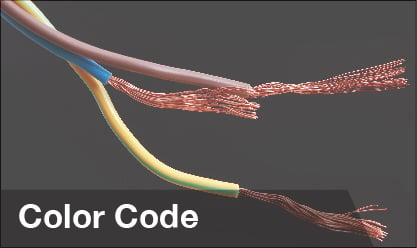

Thermo-Trex® Soaking Pit Cable is a heat-resistant cable for power applications that can withstand a maximum conductor temperature of 200°C / 392°F.

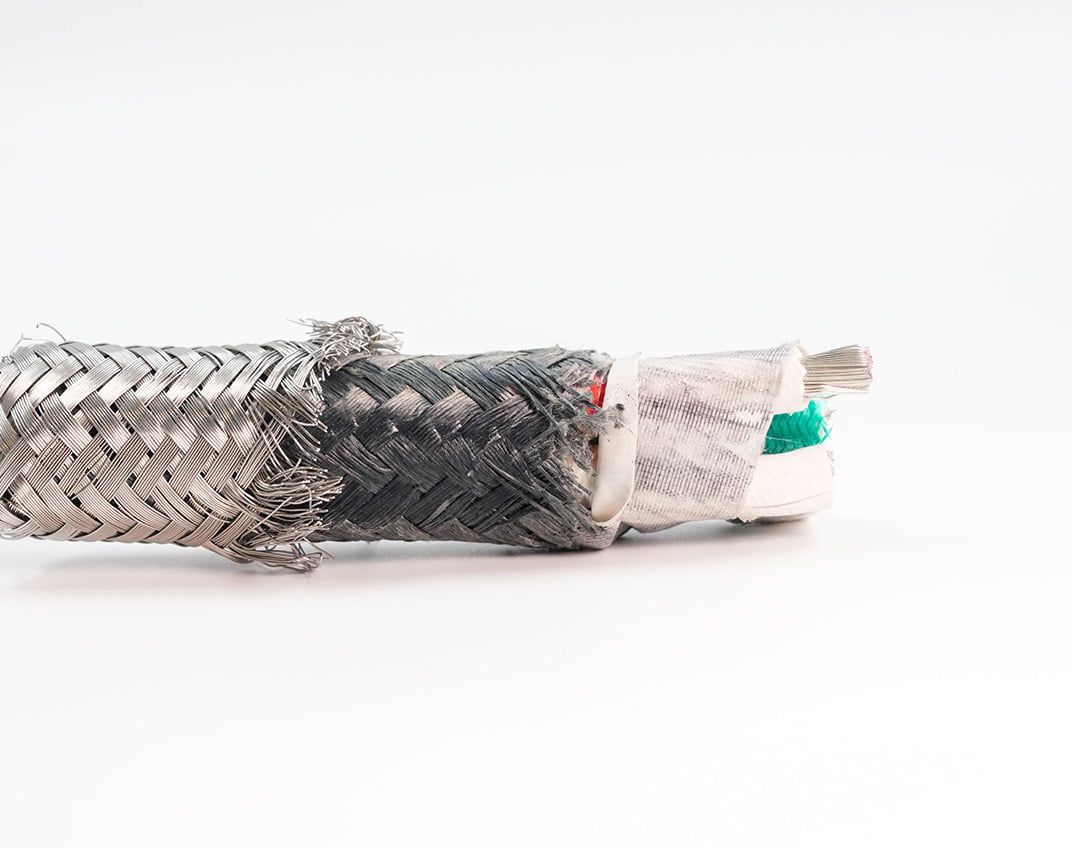

With its braided stainless steel outer jacket, this multi-conductor power cable is suited for environments where hot material contact, molten splash, and extreme mechanical abuse are common.