Thermo-Trex® Flare Stack Cable

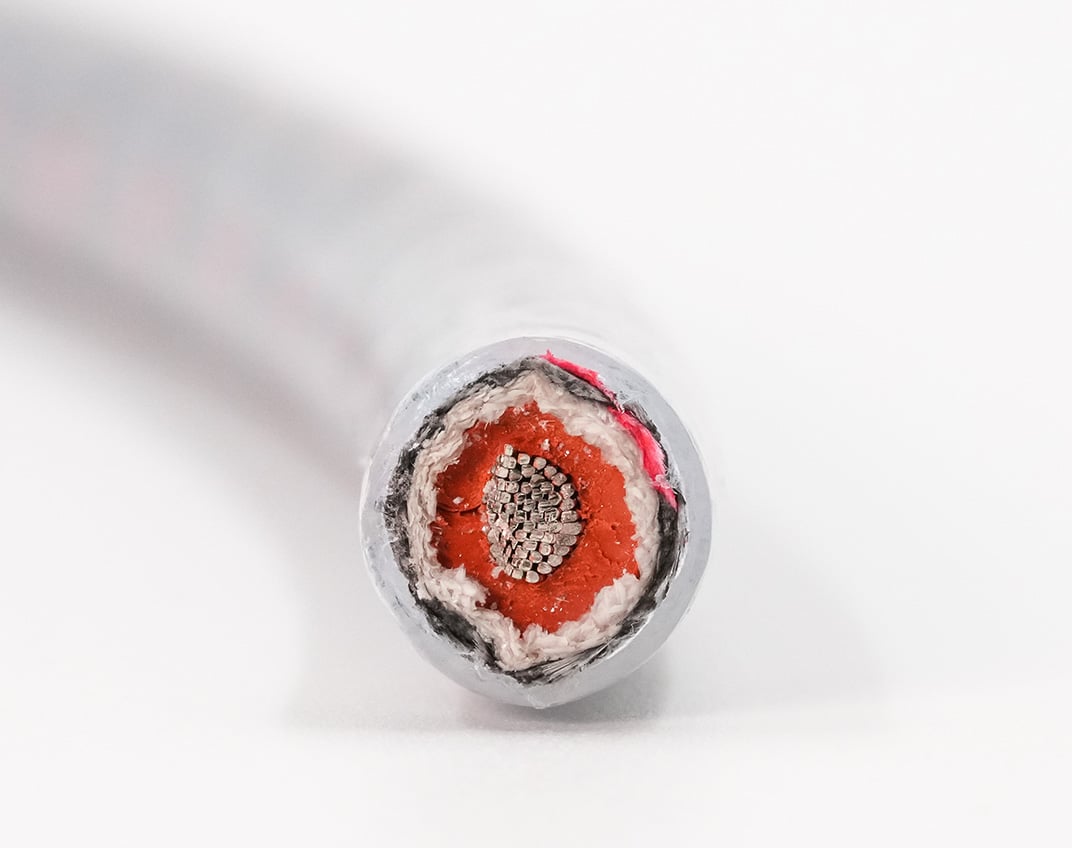

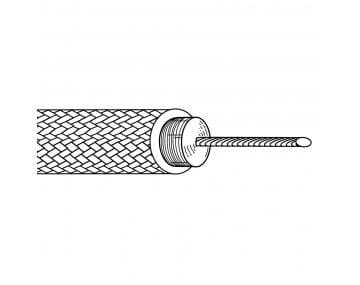

Thermo-Trex® Flare Stack Cable is a high-temperature resistant flexible cable that is suitable for all flare stack igniter applications. Its unique cable design and voltage rating is built to withstand the harshest environments to ensure ignition.

This igniter wire is voltage rated to 25kVDC and features a Fluoropolymer/ fiberglass jacket that provides protection and aids against cutting and abrasion.