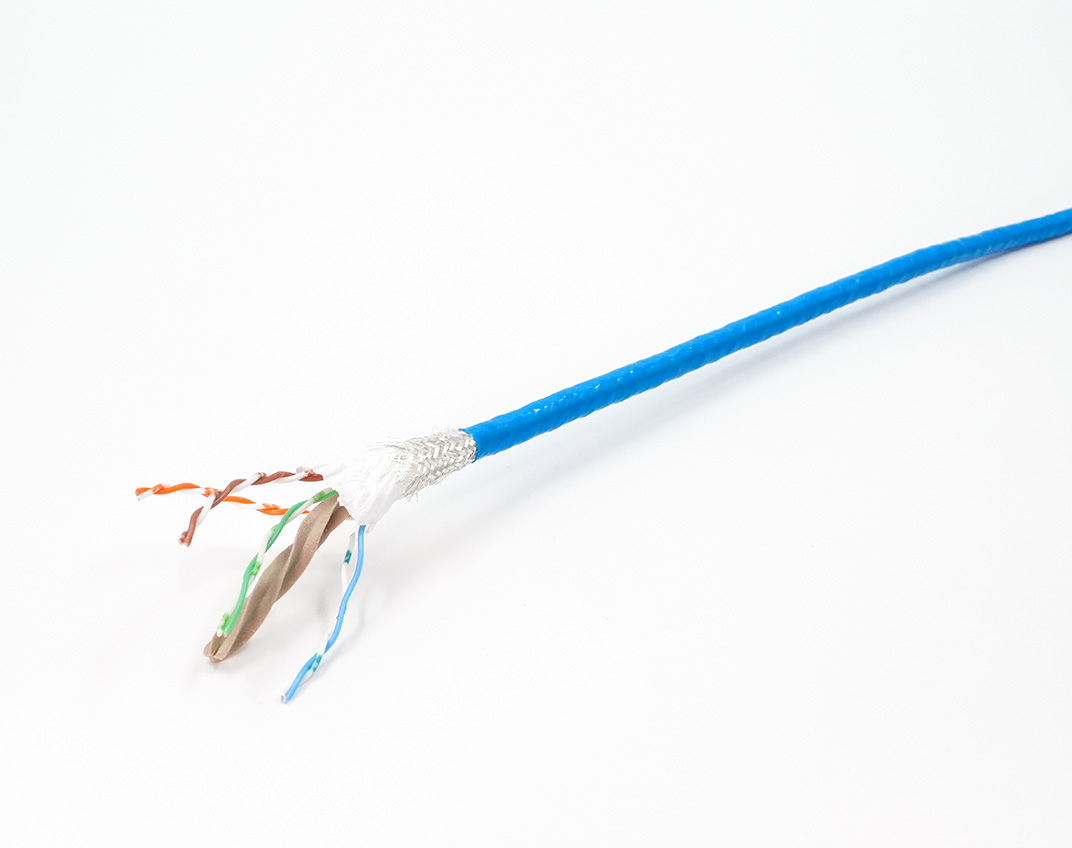

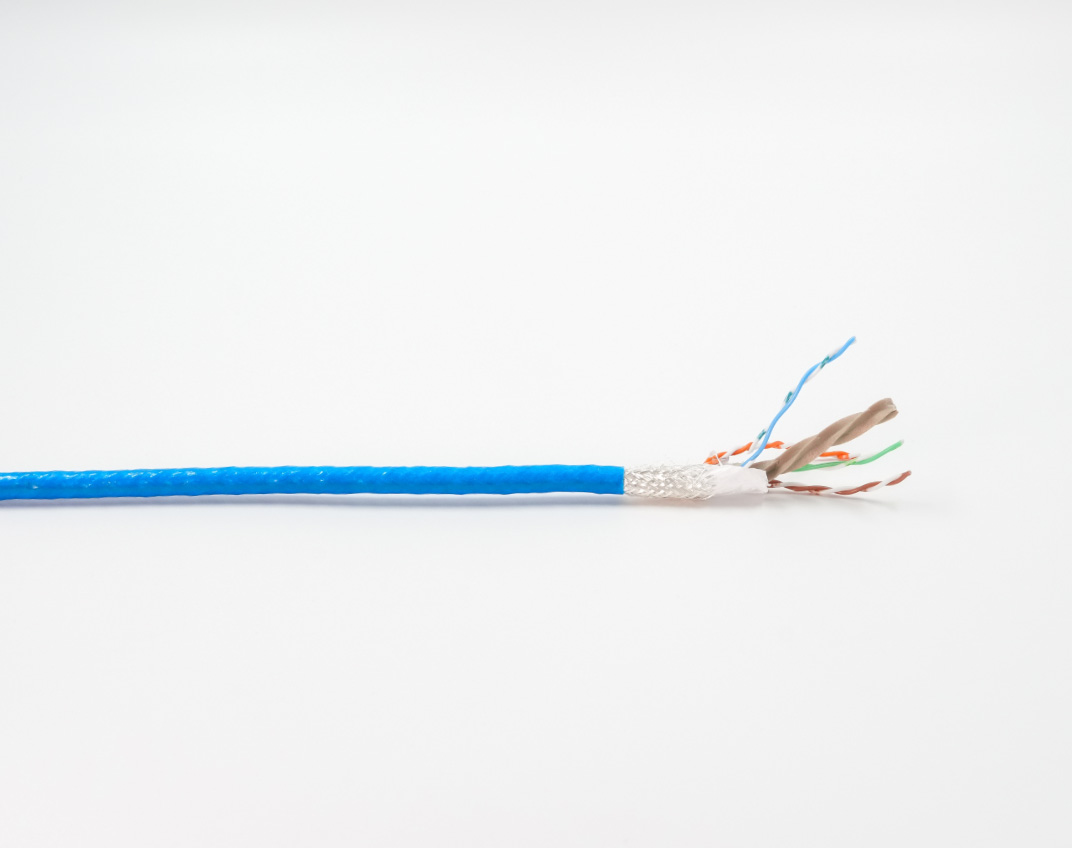

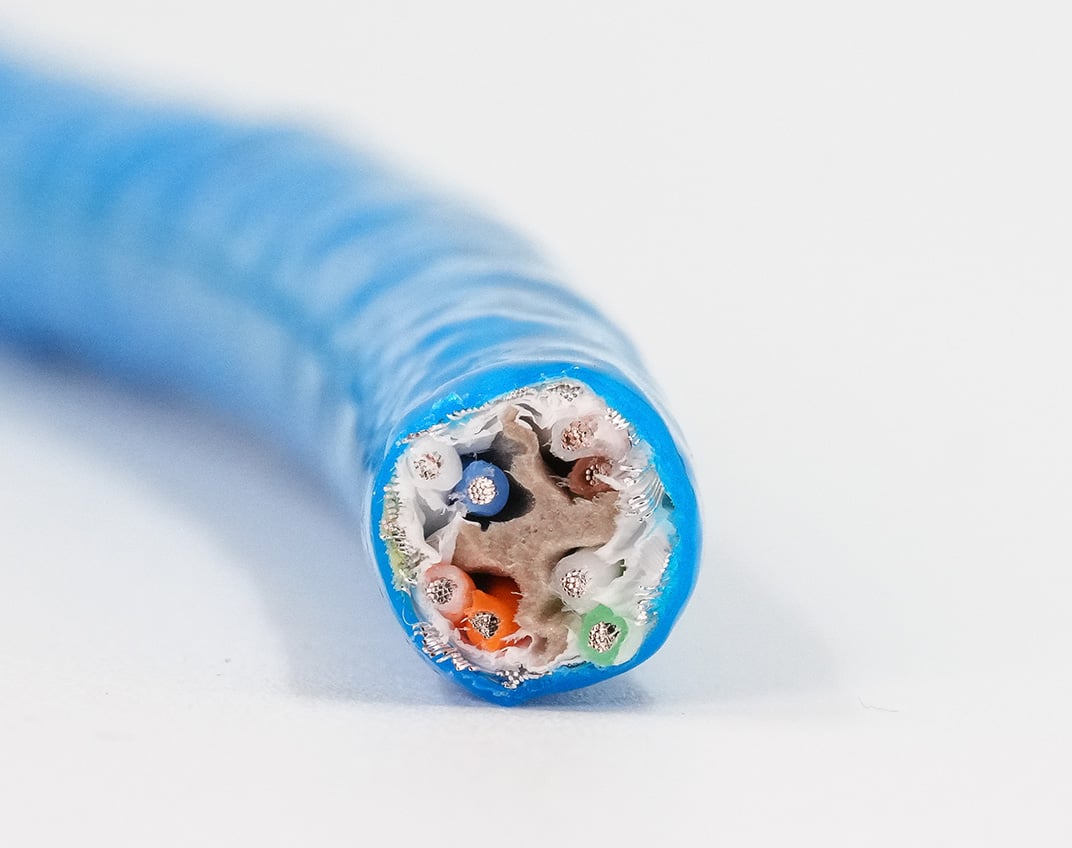

Chem-Gard® 200°C CAT6 Industrial Ethernet Horizontal Cable

Chem-Gard® 200°C CAT6 Industrial Ethernet Horizontal Cable is built for performance in the harshest of environments, including those in the metals industry. It is built to withstand a maximum conductor temperature of 200°C / 392°F.

This ethernet cable features a fluoropolymer jacket that provides excellent resistance to cutting, abrasion, oil and chemicals and is available in both shielded and non-shielded options.