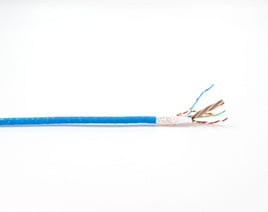

Trex-Onics® Industrial Ethernet CAT6A Cable

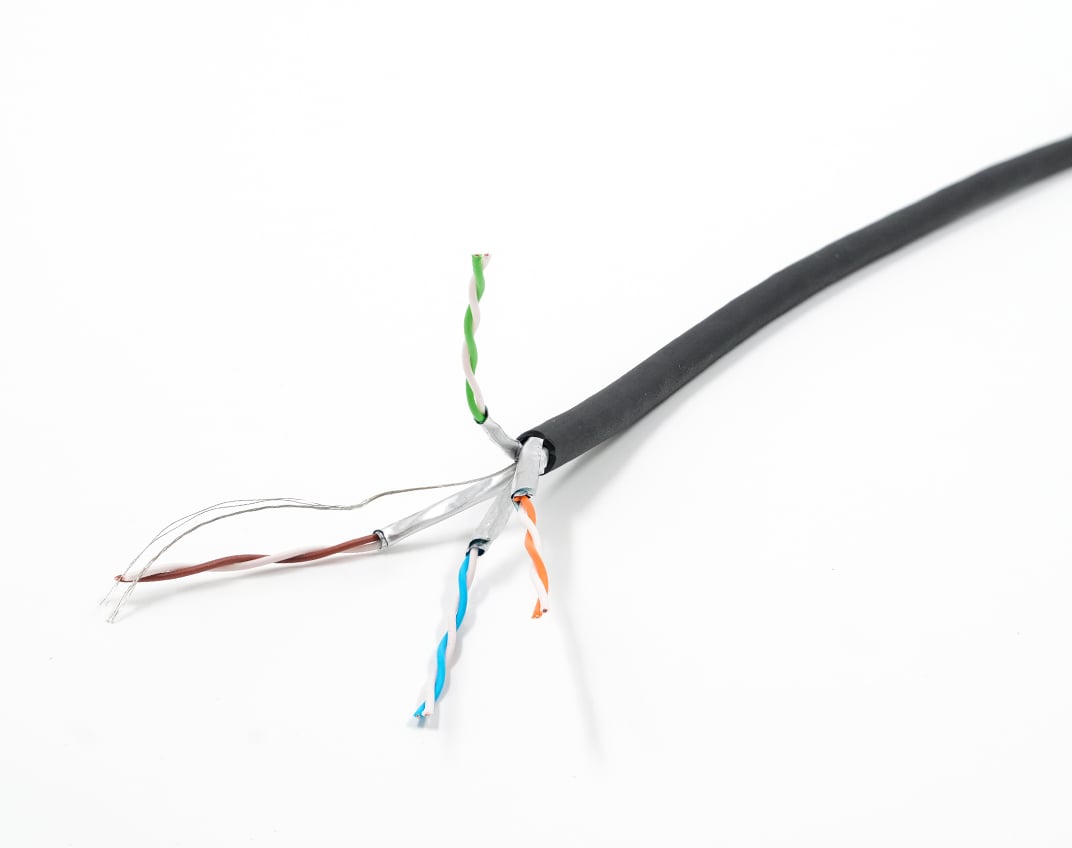

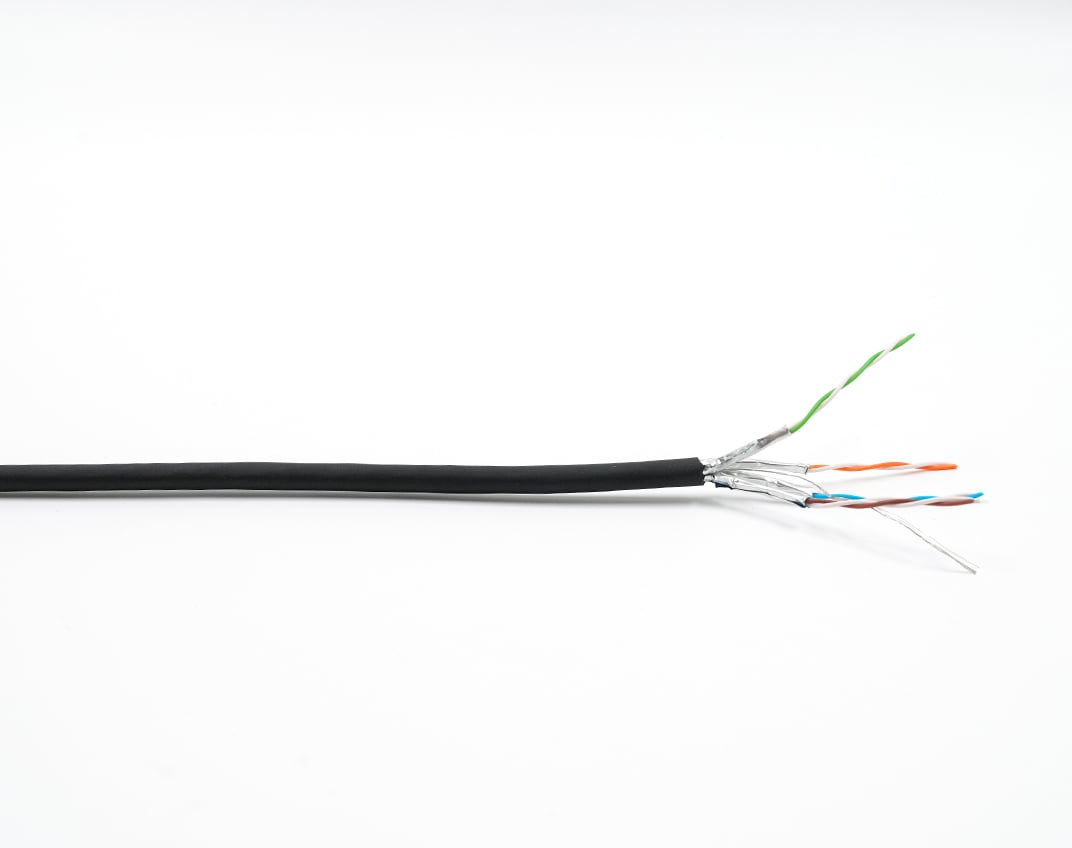

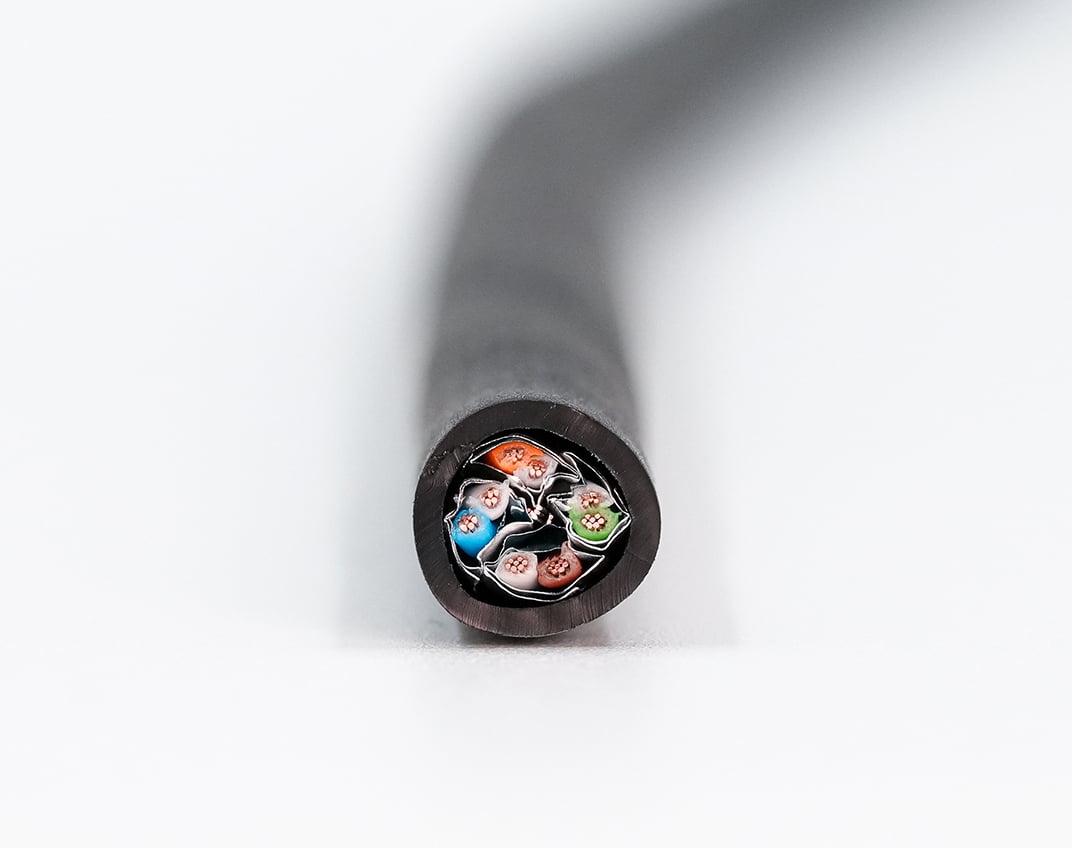

Trex-Onics® Industrial Ethernet CAT6A Cable is designed with finely stranded conductors that provide high flexibility and longer flex-life.

This ethernet cable features a halogen-free and flame-retardant jacket that provides protection from environmental abuse and offers resistance to UV light, cutting, abrasion, oil and chemicals. Our combination of cellular insulation and shielded pairs provides superior performance to meet or exceed CAT6A and Ethernet/IP requirements.