Trex-Onics® Industrial Ethernet CAT7A Cable

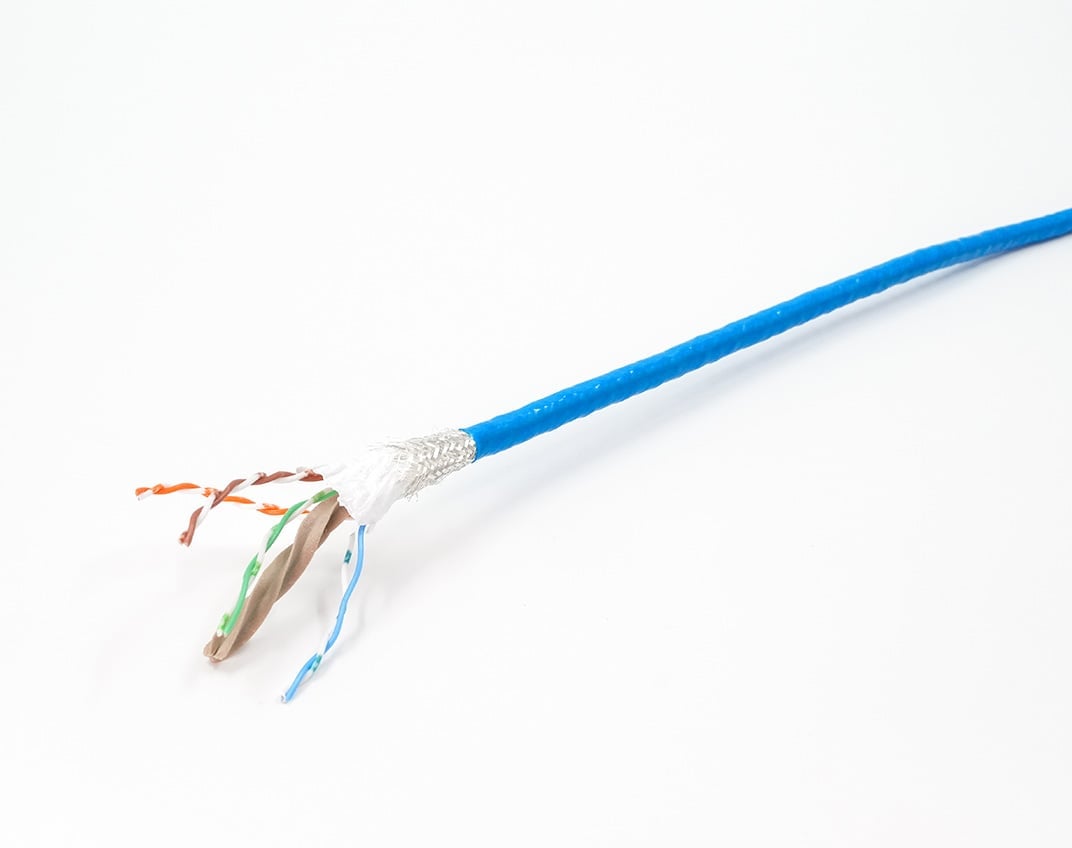

Trex-Onics® Industrial Ethernet CAT7A Cable is designed with finely stranded conductors that provide high flexibility and longer flex-life.

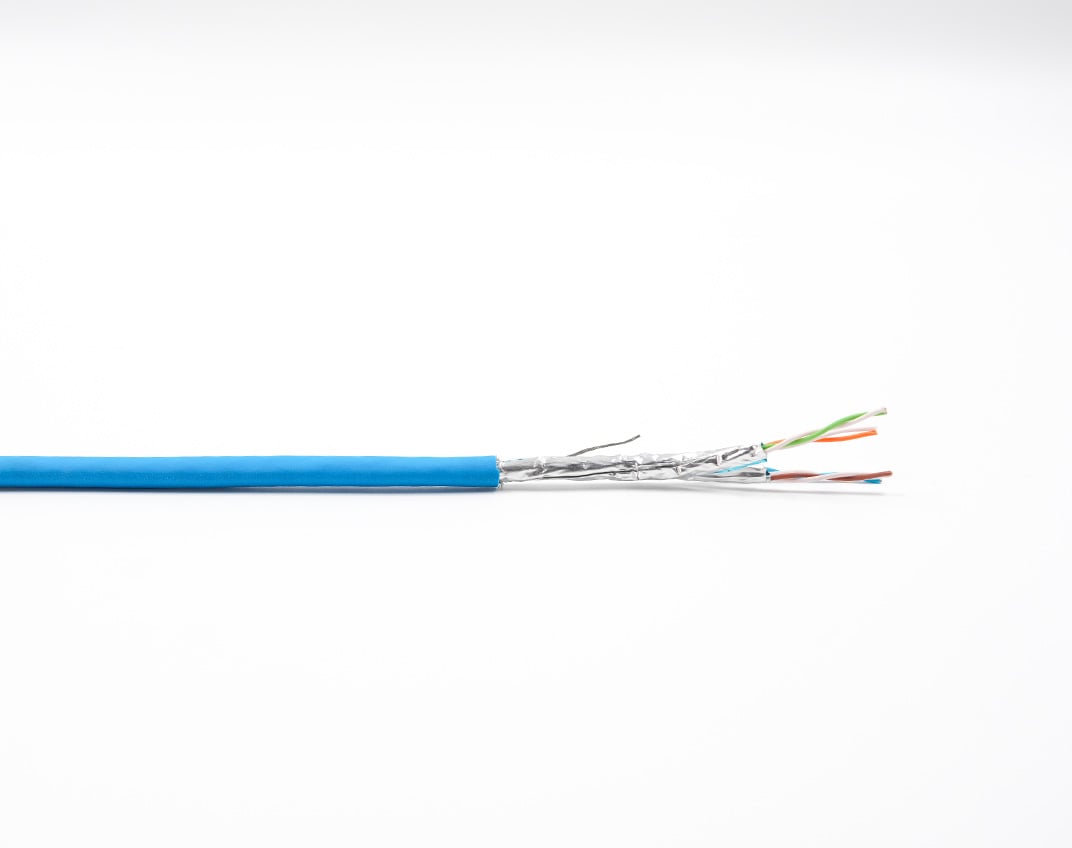

This ethernet cable features Ultra-Shield construction, which includes a heavy-duty combination of tinned copper braid, foil shield, and tinned drain wire providing 100% protection from electromagnetic and radio frequency interference. The jacket is a halogen-free, flame-retardant material that provides protection from environmental abuse and offers resistance to cutting, abrasion, oil and chemicals.