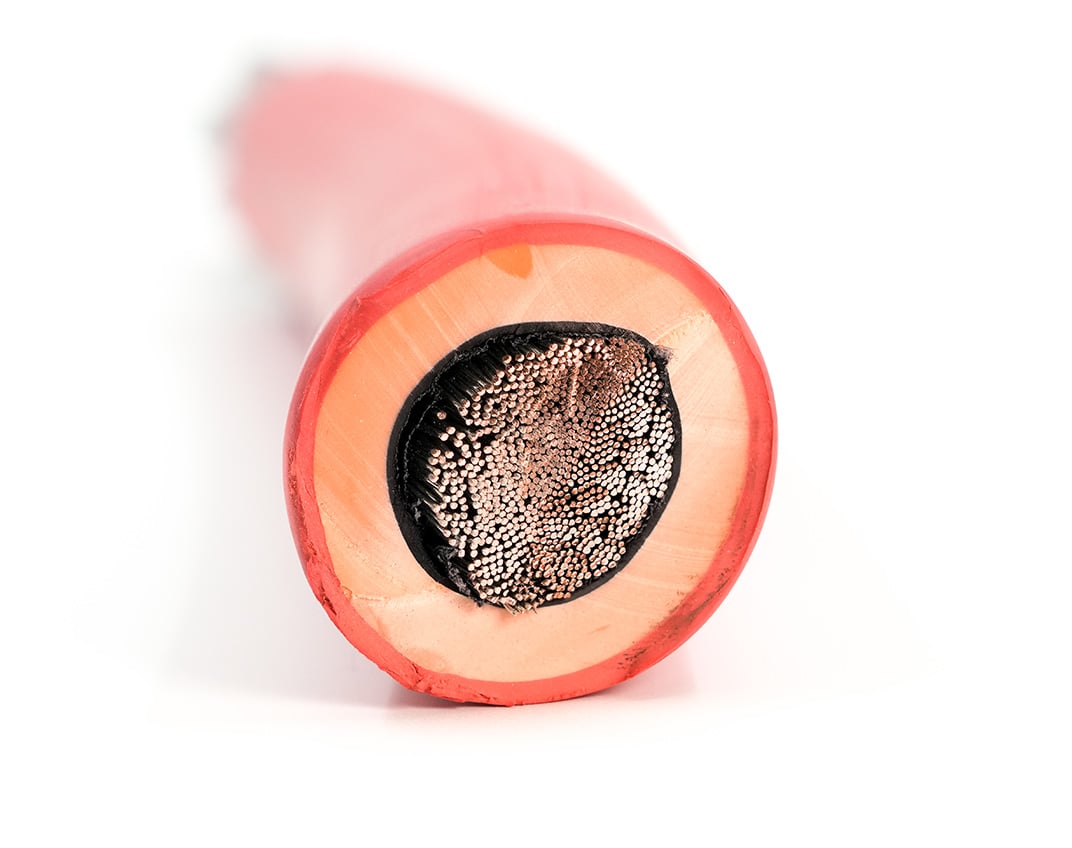

Super-Trex® Unshielded Medium Voltage Jumper Cable

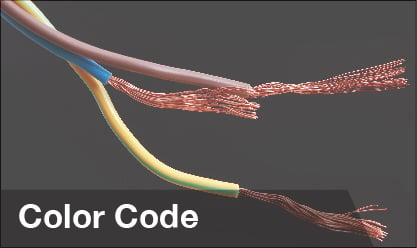

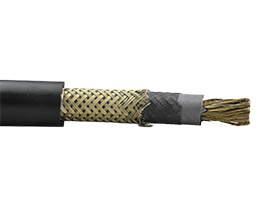

Super-Trex® Unshielded Jumper Cable is a high-flex medium voltage single-conductor cable designed for temporary use. It is an ideal choice for industrial applications where an unshielded medium voltage cable is suitable. This includes temporary by-passing of damaged sections of power cable, or in areas such as switchgear enclosures or transformer vaults.