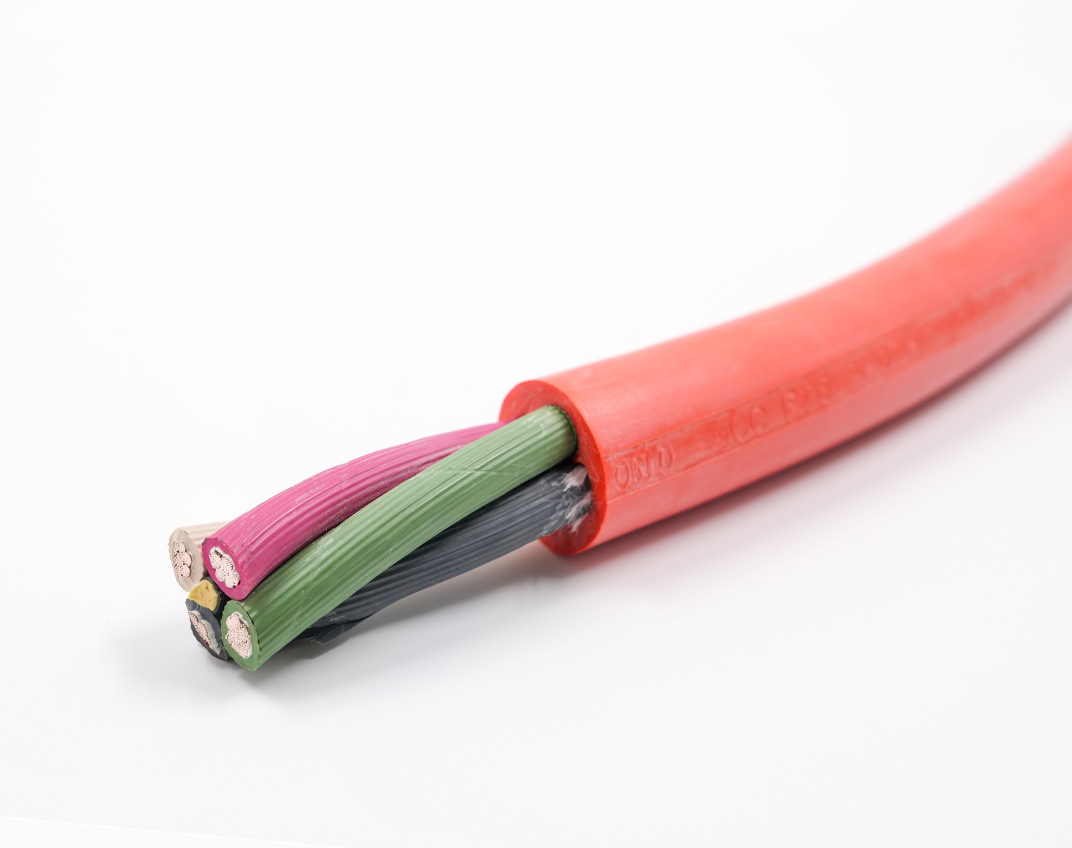

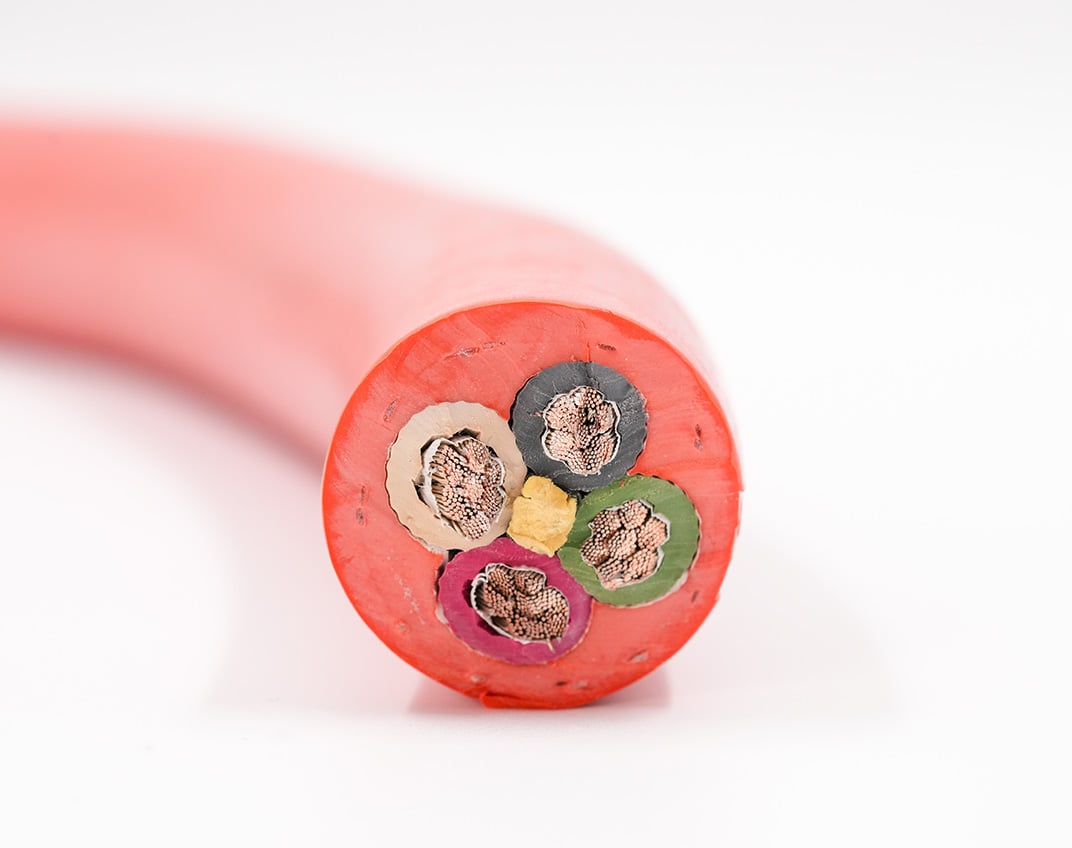

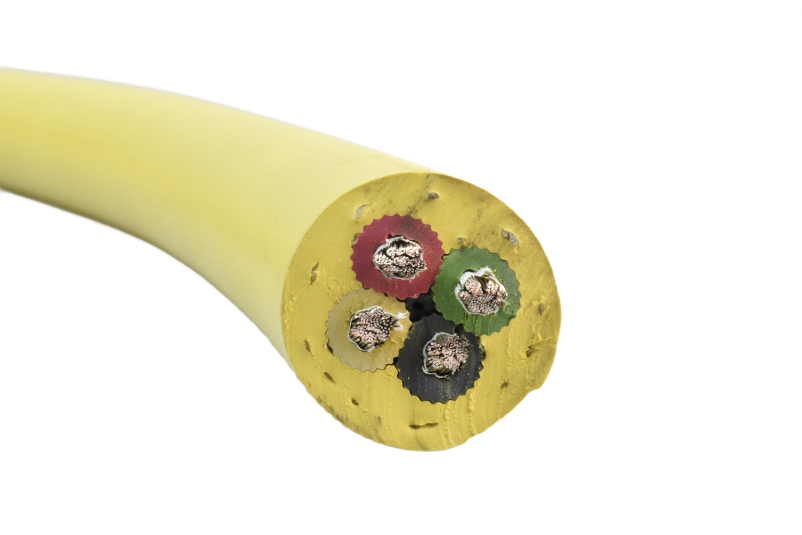

Super-Trex® 4-Conductor Aramid Reinforced Portable Power Reeling Cable

Super-Trex® 4-Conductor Aramid Reinforced Orange Portable Power Reeling Cable is an excellent cable for high tension reeling applications and is designed with an aramid center strength member providing up to 4,000 pounds of break strength. This Type W portable power cable features an integral filled, dual-layered fiber-reinforced jacket for added strength and resistance to twisting and pulling. The orange TSE jacket provides excellent protection against abrasion, impact and most industrial chemicals.

.jpg)