When it comes to heavy-duty crane and reeling applications, the choice in cable needs to provide excellent service, resist corkscrewing and provide long-term reliability. TPC's line of reeling cables are designed with the highest quality compounds to provide longer flex life in heavy-duty applications prone to impact, vibration, tension, abrasion, pulling, flexing, oil, chemicals, extreme temperatures.

Super-Trex® Multi-Conductor P&R Cable is designed specifically for payout and retractile (P&R) reeling applications.

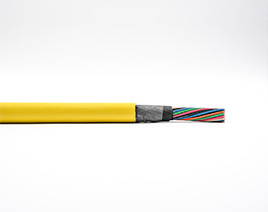

Super-Trex® 4-Conductor Aramid Reinforced Orange Portable Power Reeling Cable is an excellent cable for high tension reeling applications and is designed with an aramid center strength member providing up to 4,000 pounds of break strength.

Trex-Onics® Reduced Diameter Extra Heavy Duty Reeling Cable is ideal for reeling, cat tracks and theater/stage lighting.

Thermo-Trex® High Temp Reeling Cable is a high temperature cable for reeling applications that can withstand a maximum conductor temperature of 200°C / 392°F.