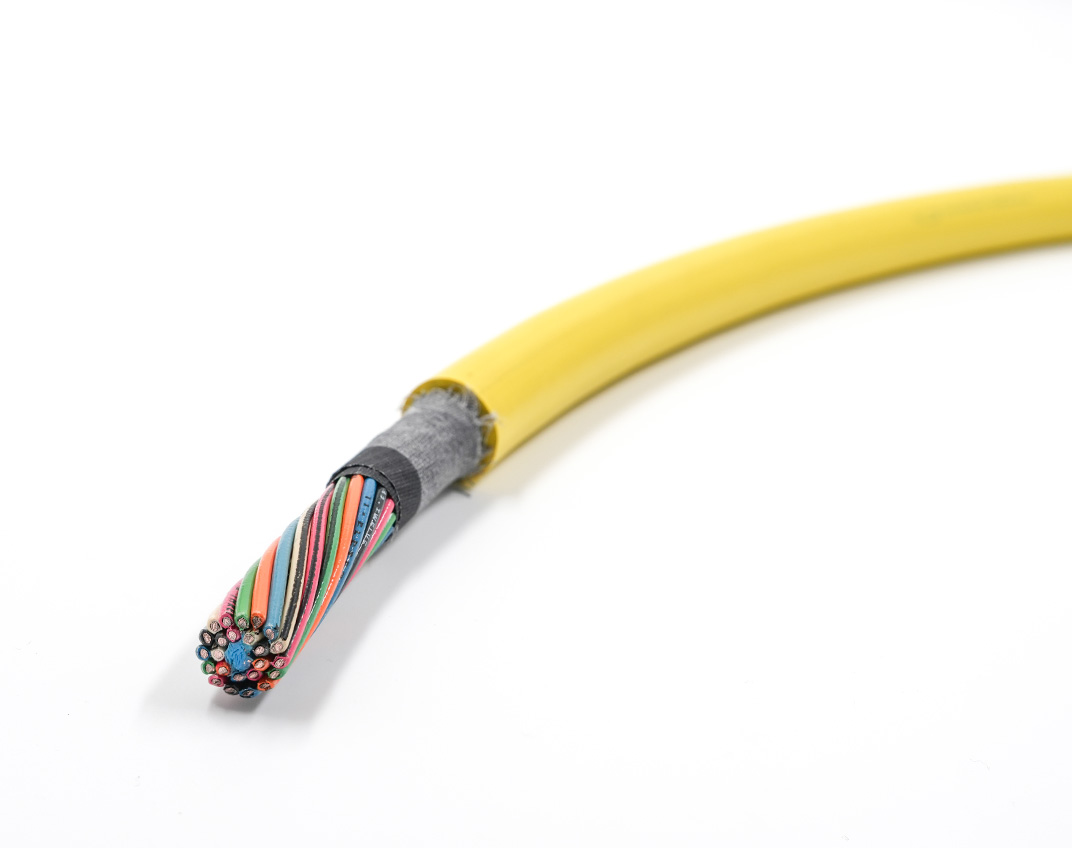

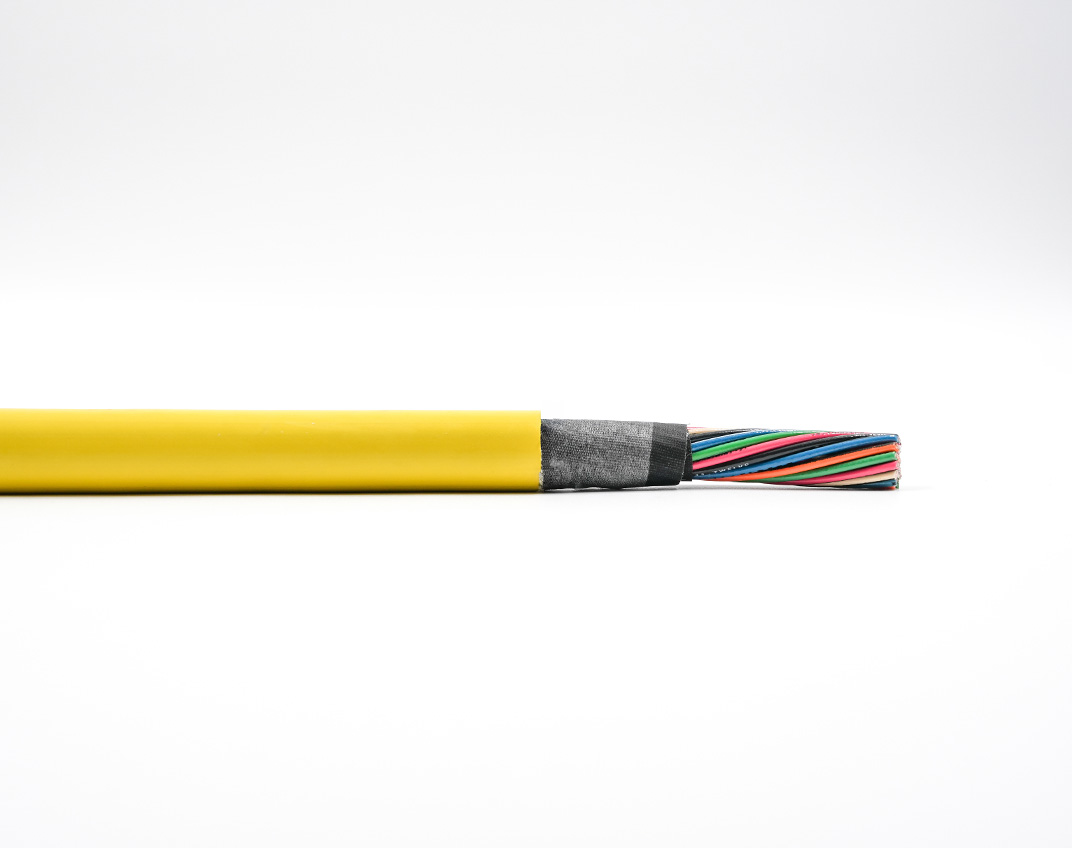

Super-Trex® Multi-Conductor P&R Cable

Super-Trex® Multi-Conductor P&R Cable is designed specifically for payout and retractile (P&R) reeling applications.

This P&R cable features our live-flex conductor insulation for increased flexibility and high dielectric, tensile and mechanical properties. A security yellow TSE dual-layer jacket provides protection against abuse tearing, abrasion, impact, oil, chemicals. This product is ideal for use in applications that see direct flame.

.jpg)