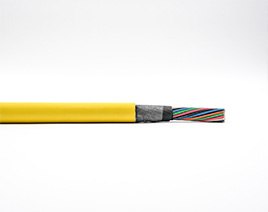

Thermo-Trex® High Temp Reeling Cable

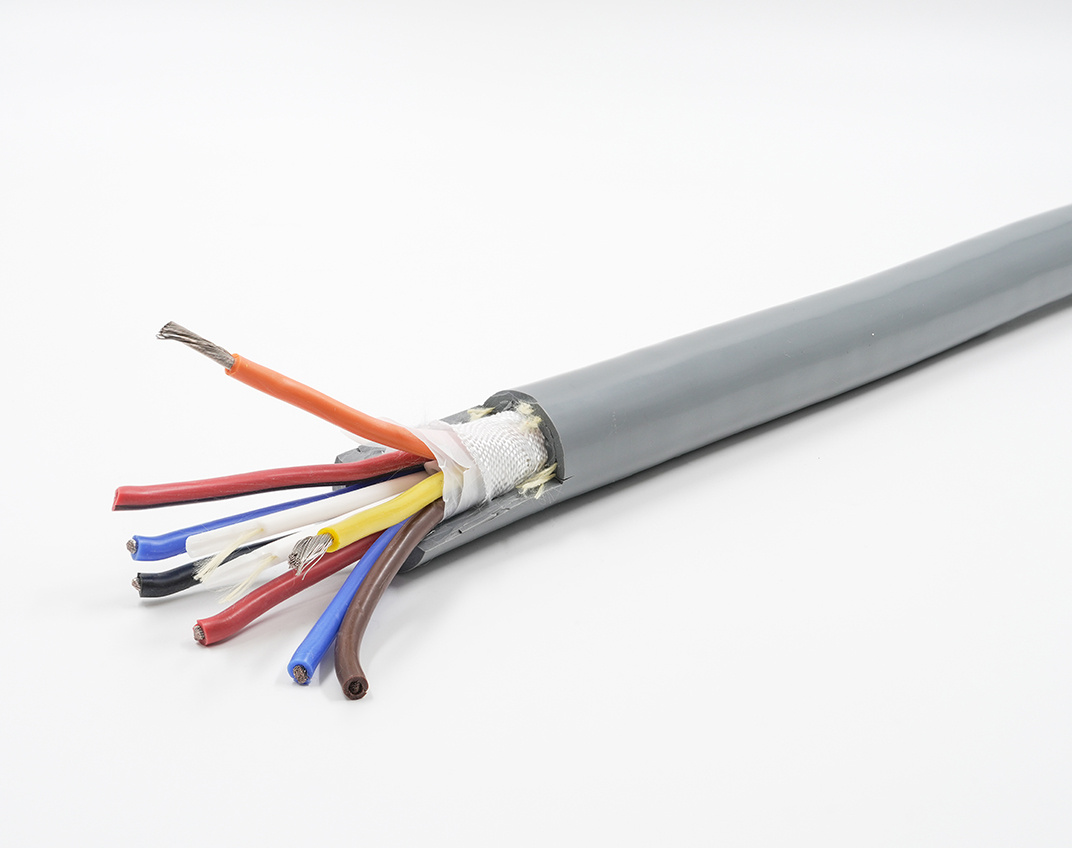

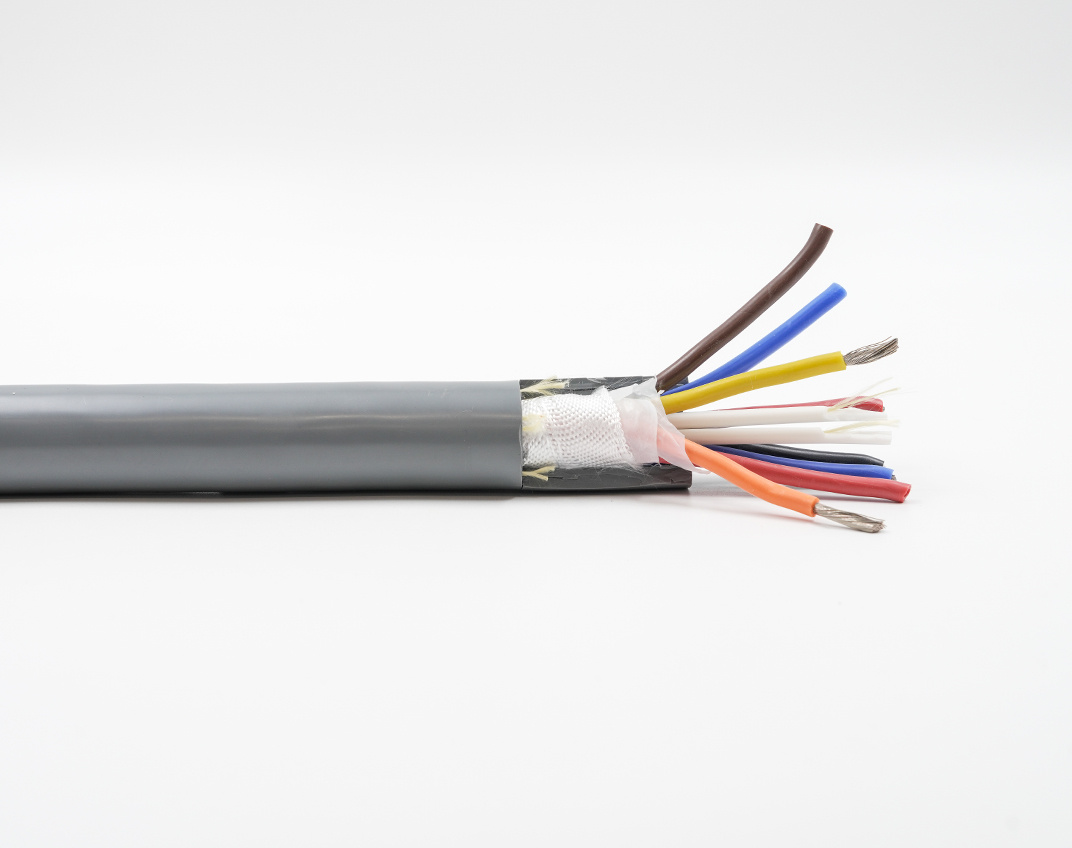

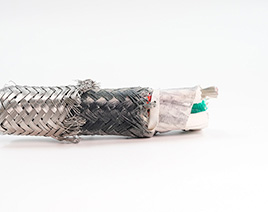

Thermo-Trex® High Temp Reeling Cable is a high temperature cable for reeling applications that can withstand a maximum conductor temperature of 200°C / 392°F. This reeling cable features a double-pass reinforced silicone jacket with an aramid center strength member for resistance to twisting and pulling in high tension applications.