Trex-Onics® Reduced Diameter Extra Heavy Duty Reeling Cable

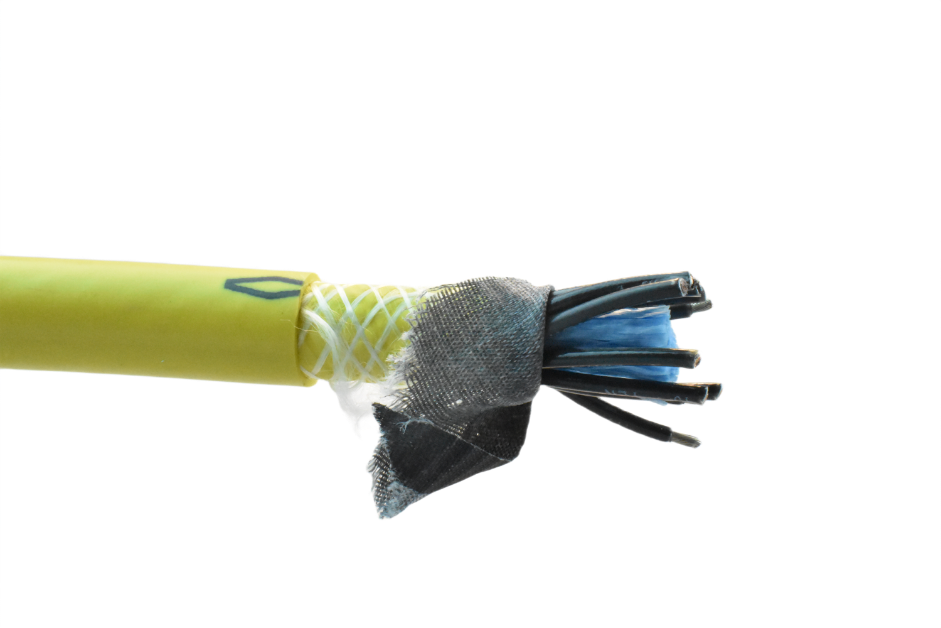

Trex-Onics® Reduced Diameter Extra Heavy Duty Reeling Cable is ideal for reeling, cat tracks and theater/stage lighting. The strength of this cable is complemented with tinned conductors to provide a longer life in flexing and twisting applications.

This reeling cable features a reinforced aramid braid embedded in the jacket rated at 1,800 lbs. tensile strength for tensile reeling applications. This cable also has TPE conductor insulation for a very low coefficient of friction and superior dielectrics.

.jpg)