Trex-Onics® High-Flex Ultra Coil Retractile Cord

Trex-Onics® High-Flex Ultra Coil Retractile Cord exhibits a unique design that provides a very durable yet lightweight retractile cord while preserving superior coil retention and snappiness.

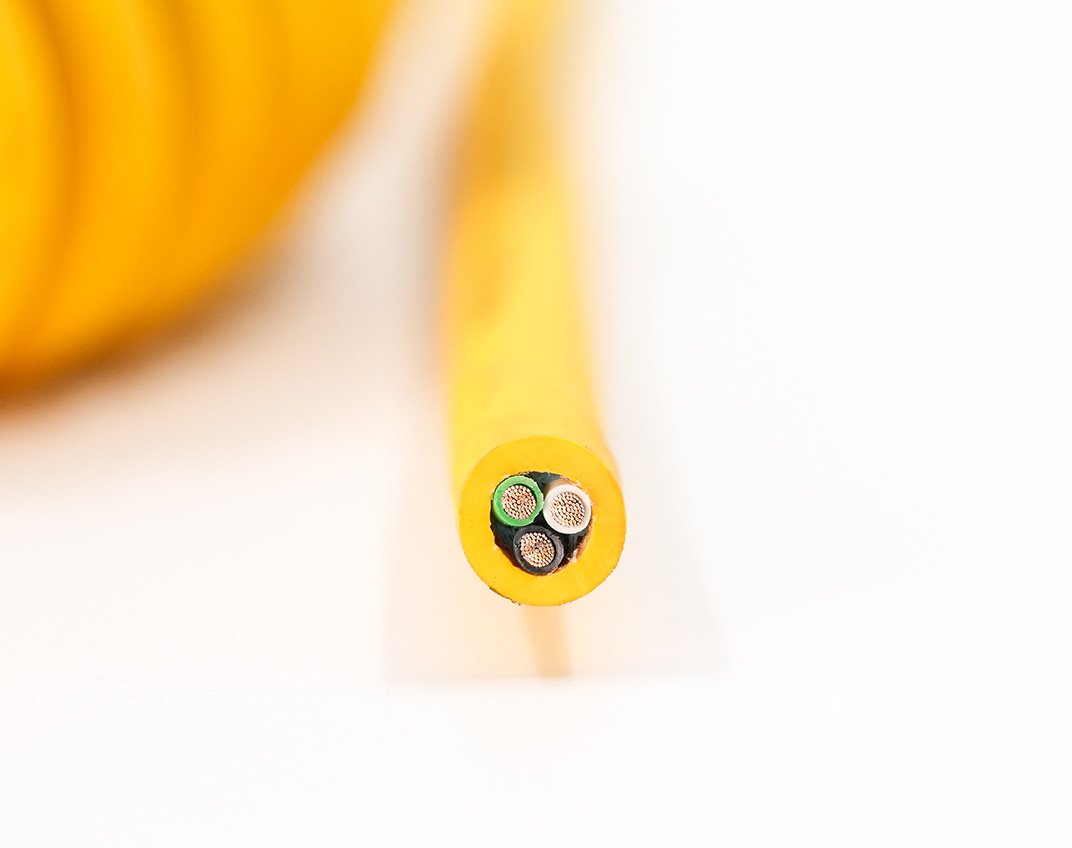

This control and instrumentation cable features a heavy-duty security yellow polyurethane jacket that protects against cutting, abrasion, oil and chemicals. Also available as Quick-Connex® Mini or Micro cord

.jpg)