Amphenol TPC Wire & Cable products are designed to withstand the common challenges that cause ordinary wire and cable to fail. Our reputation has been built on reducing downtime by supplying a longer lasting product to the markets we serve. With a full range of wire, cable and connector products, we offer a high performance solution and value-added service for just about every industrial application.

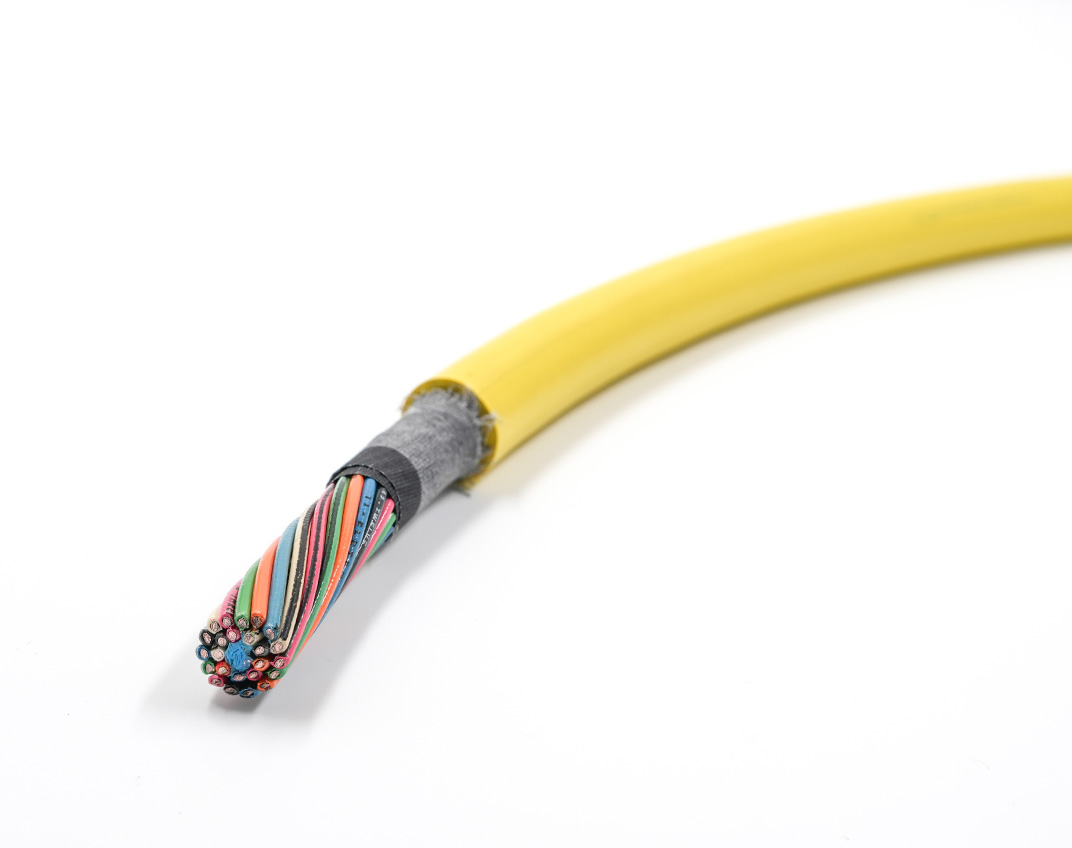

We're the industry leader in high-end electrical wire and cable used in demanding and abusive applications. Our rugged products are designed to withstand abuse from impact, abrasion, continuous flexing, caustic chemicals, and extreme temperatures. Our highly experienced team of electrical cable engineers boast over 40 years crafting high-performance wires and cable solutions tested specifically for harsh environments.

Along with our standard and custom wire and cable products, we offer a comprehensive assortment of useful cable accessories to help you avoid the frustration of unnecessary downtime and perform regular electrical maintenance safely, accurately, and efficiently. We have a complete assortment of industrial-grade cable straps, cable sleeving, electrical components, tape, and tools that make great additions to any toolbox.

Our Cordsets offer you a wide range of products to make the replacement of electrical and electronic control devices quick and simple. Choose from Mini, Micro and Nano assemblies in various lengths as well as wire gauges and jacket materials specific to your application. Fully molded assemblies in standard and custom lengths are available featuring nickel and gold plated solid brass pins, integrated LEDs and Ingress Protection.

TPC Wire & Cable has over 35 years of experience building high-quality cable assemblies for a variety of customers and applications. Our hands-on knowledge of the industry combined with a state-of-the-art design center allows us to provide you the high-performance cable assemblies you demand.

TPC is your custom cable solutions provider. TPC strives to deliver our customers innovative and high-performance industrial wire and cable. We understand the many applications and harsh industrial environments your industry faces. Sometimes you need a custom solution that is customized to your requirements and application needs.

Electrical components refer to the individual parts or devices that make up an electrical system. Electrical components are used in a wide range of applications, from simple circuits to complex electronic systems. They are typically designed to perform specific functions and work together to create a complete electrical system. Choosing the right electrical components for a given application is essential to ensure safe and efficient operation of the system.

Amphenol TPC Wire & Cable designs custom cable storage and deployment systems that improve efficiency in the field.