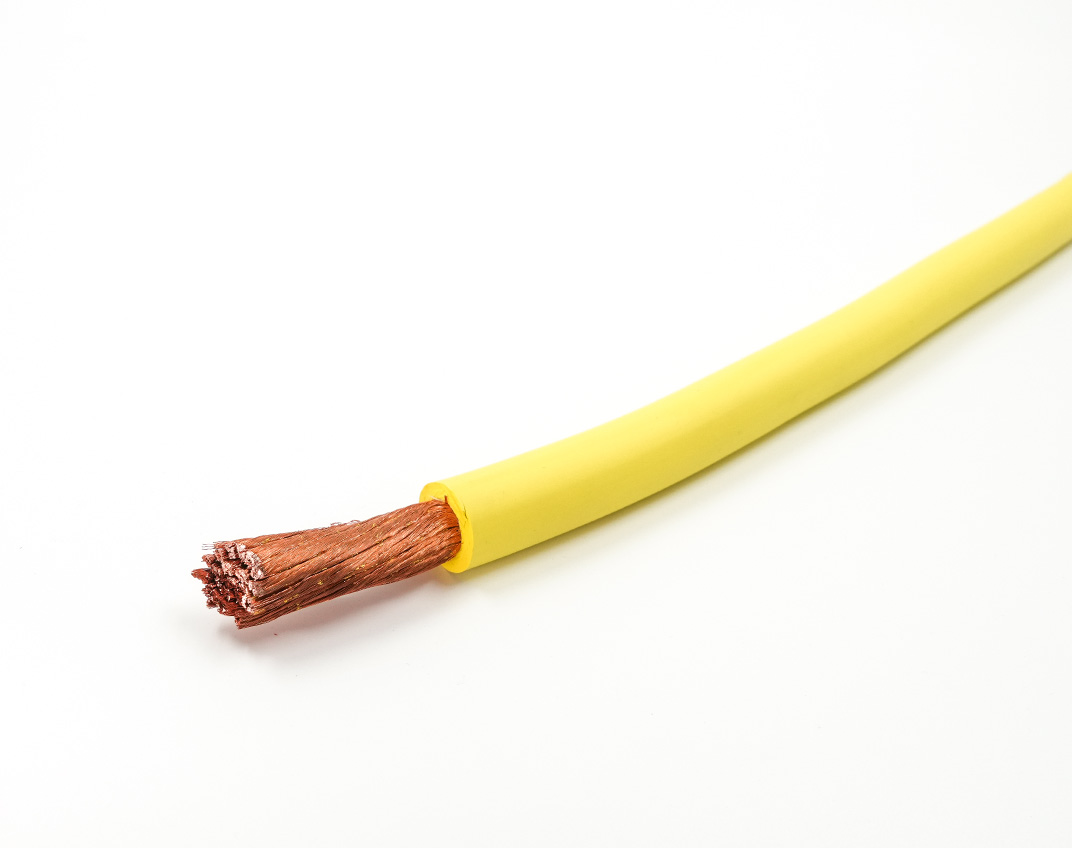

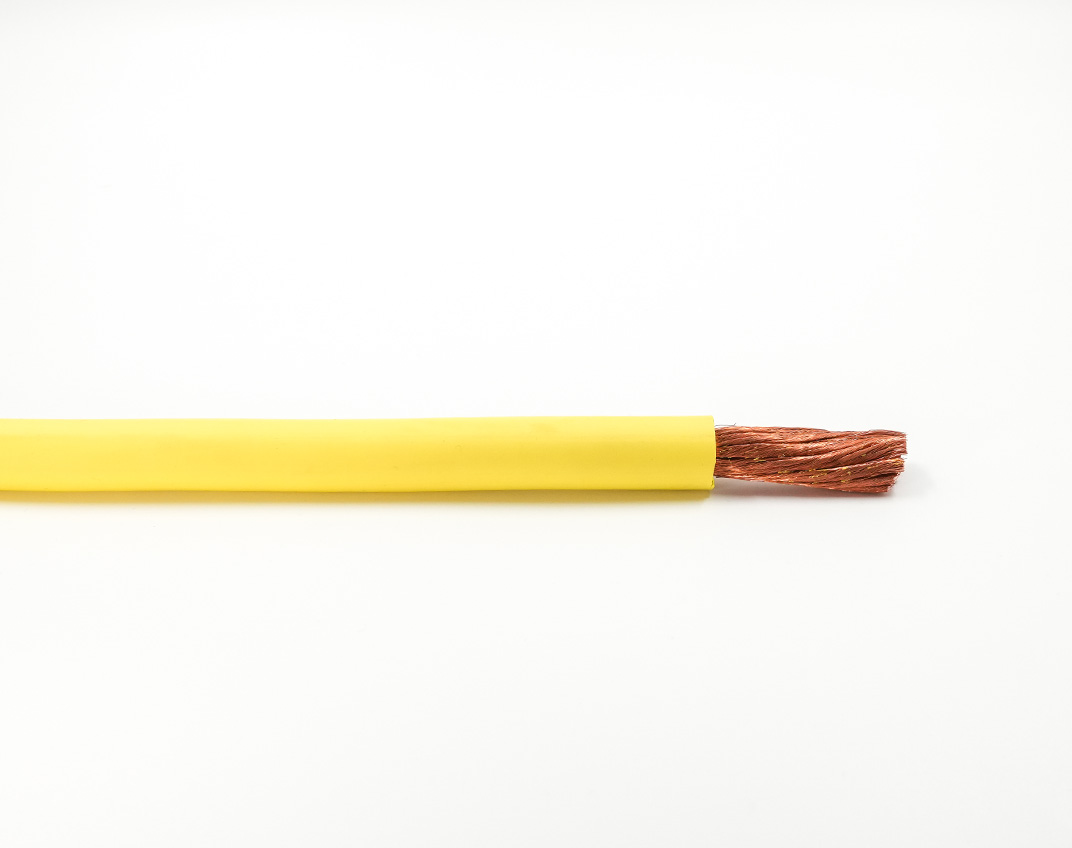

Super-Trex® 600 Volt Welding Cable

Super-Trex® 600 Volt Welding Cable is designed for rugged use and is ideal for welding in industrial environments. This welding cable features our extra-flex highly stranded conductor, a TSE jacket, and 100% fabric serve to resist tearing and shrink back. This welding cable also withstands abrasion, impact, and chunking, extending the life of the cable in harsh applications.

%20PNG.png)