We stand apart from other industrial wire and cable suppliers because we do so much more than simply supply high-quality products. Our engineers and product managers work closely with you to provide custom solutions for your most demanding industrial applications. There is no job that our team can’t tackle. Our engineering team is ready to design a custom solution for you!

We have a diverse team of electrical, industrial, and mechanical engineers to help design custom cables that are engineered for your specific challenges.

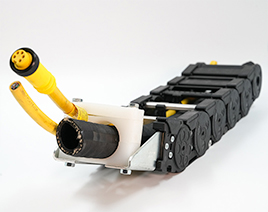

Our custom solutions also include connectors, assemblies, cable carriers, and storage and deployment systems.

No video selected

Select a video type in the sidebar.