| 68809 |

24 AWG |

9 |

19/36 |

4 |

0.006 |

26 AWG |

26 AWG |

0.045 |

0.4 |

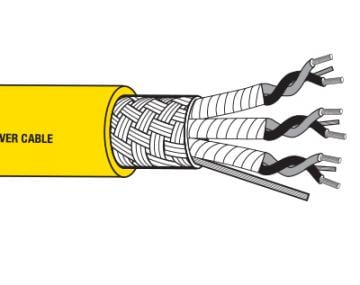

Overall Shielded, Individually Shielded Pairs |

| 68807 |

24 AWG |

7 |

19/36 |

4 |

0.006 |

26 AWG |

26 AWG |

0.045 |

0.33 |

Overall Shielded, Individually Shielded Pairs |

| 68806 |

24 AWG |

6 |

19/36 |

6 |

0.006 |

26 AWG |

26 AWG |

0.045 |

0.33 |

Overall Shielded, Individually Shielded Pairs |

| 68804 |

24 AWG |

4 |

19/36 |

7 |

0.006 |

26 AWG |

26 AWG |

0.045 |

0.3 |

Overall Shielded, Individually Shielded Pairs |

| 68803 |

24 AWG |

3 |

19/36 |

7 |

0.006 |

26 AWG |

26 AWG |

0.045 |

0.265 |

Overall Shielded, Individually Shielded Pairs |

| 68802 |

24 AWG |

2 |

19/36 |

8 |

0.006 |

26 AWG |

26 AWG |

0.045 |

0.275 |

Overall Shielded, Individually Shielded Pairs |

| 68709 |

22 AWG |

9 |

19/34 |

6 |

0.006 |

24 AWG |

24 AWG |

0.045 |

0.45 |

Overall Shielded, Individually Shielded Pairs |

| 68707 |

22 AWG |

7 |

19/34 |

6 |

0.006 |

24 AWG |

24 AWG |

0.045 |

0.37 |

Overall Shielded, Individually Shielded Pairs |

| 68706 |

22 AWG |

6 |

19/34 |

8 |

0.006 |

24 AWG |

24 AWG |

0.045 |

0.37 |

Overall Shielded, Individually Shielded Pairs |

| 68704 |

22 AWG |

4 |

19/34 |

9 |

0.006 |

24 AWG |

24 AWG |

0.045 |

0.315 |

Overall Shielded, Individually Shielded Pairs |

| 68703 |

22 AWG |

3 |

19/34 |

9 |

0.006 |

24 AWG |

24 AWG |

0.045 |

0.3 |

Overall Shielded, Individually Shielded Pairs |

| 68702 |

22 AWG |

2 |

19/34 |

11 |

0.006 |

24 AWG |

24 AWG |

0.045 |

0.275 |

Overall Shielded, Individually Shielded Pairs |

| 68609 |

20 AWG |

9 |

19/32 |

6 |

0.006 |

22 AWG |

22 AWG |

0.045 |

0.5 |

Overall Shielded, Individually Shielded Pairs |

| 68607 |

20 AWG |

7 |

19/32 |

7 |

0.006 |

22 AWG |

22 AWG |

0.045 |

0.41 |

Overall Shielded, Individually Shielded Pairs |

| 68606 |

20 AWG |

6 |

19/32 |

7 |

0.006 |

22 AWG |

22 AWG |

0.045 |

0.41 |

Overall Shielded, Individually Shielded Pairs |

| 68604 |

20 AWG |

4 |

19/32 |

10 |

0.006 |

22 AWG |

22 AWG |

0.045 |

0.35 |

Overall Shielded, Individually Shielded Pairs |

| 68603 |

20 AWG |

3 |

19/32 |

10 |

0.006 |

22 AWG |

22 AWG |

0.045 |

0.315 |

Overall Shielded, Individually Shielded Pairs |

| 68602 |

20 AWG |

2 |

19/32 |

13 |

0.006 |

22 AWG |

22 AWG |

0.045 |

0.305 |

Overall Shielded, Individually Shielded Pairs |

.jpg)