Trex-Onics® Reduced Diameter Power Cable

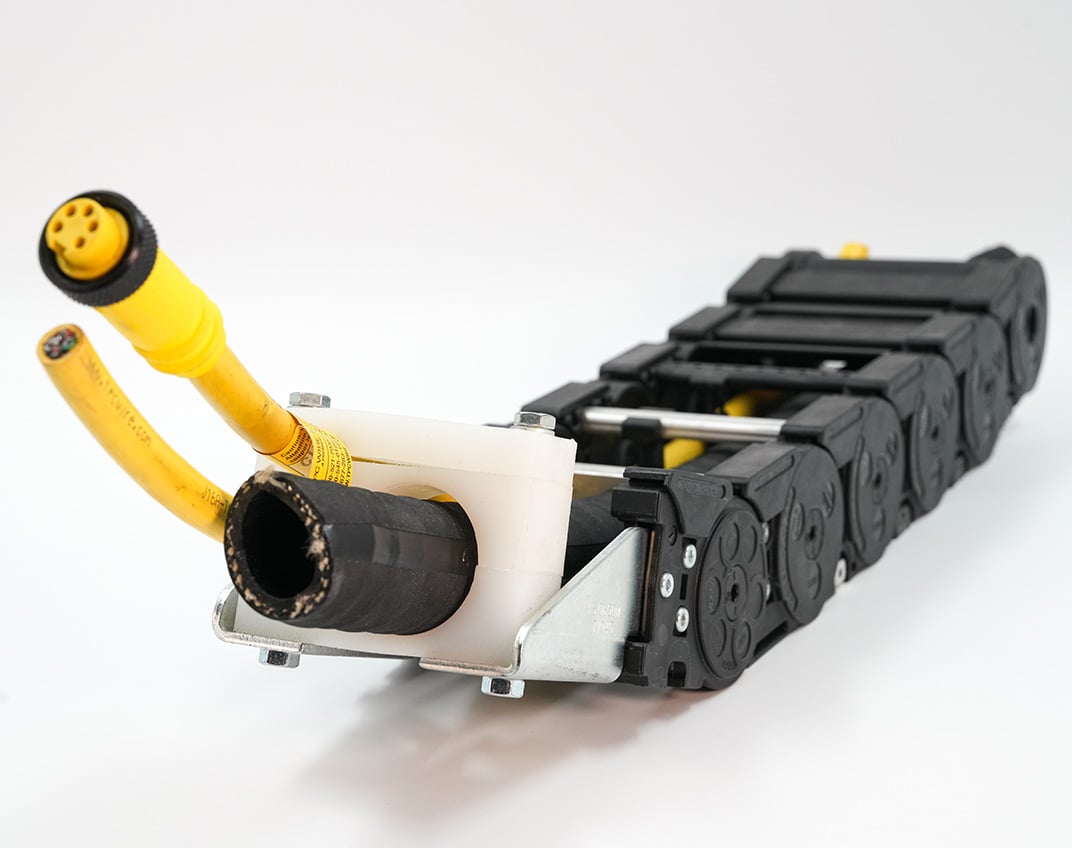

Trex-Onics® Reduced Diameter Power Cable is designed for continuous flexing applications.

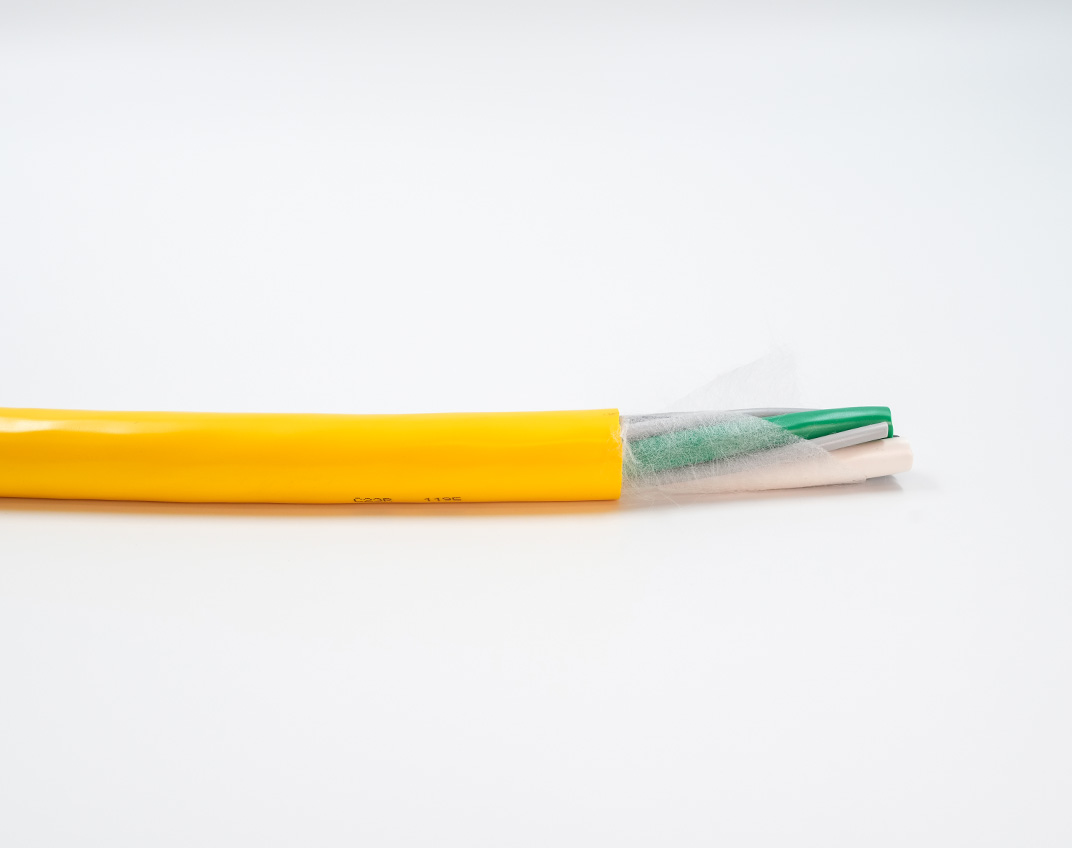

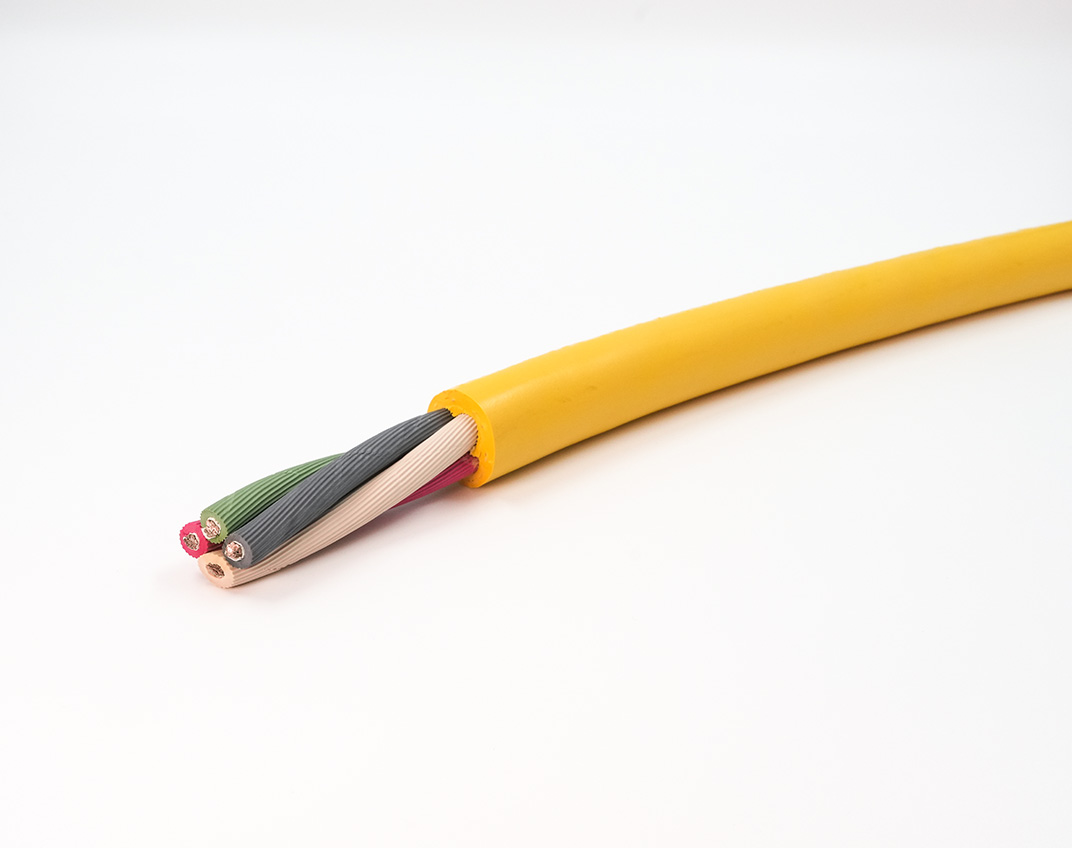

This flexible power cable features extra-fine conductor stranding and unique tubed construction, allowing the conductors to move freely and not bind. The security yellow TPE jacket is the first line of defense against tearing, abrasion, impact, oil, and most chemicals.