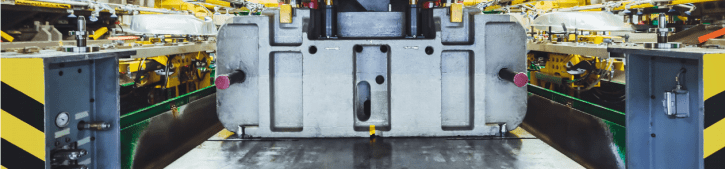

A large vehicle manufacturing plant in Kentucky was replacing bolster cable on its stamping press every 10-11 months due to failure. The inner conductors would fatigue, deteriorate, and ultimately fail from constant environmental pressures that included flexing, motion, and tension. In addition, the outer jacket was being abraded and cut by metal scrap in the area. Over the course of 32 months, the failures added up to $12,767 in product and labor expenses plus, as a result, the application was down for 53 hours total during that time period.

The customer’s TPC representative worked with TPC’s in-house engineering team to develop a custom solution stemming from the Trex-Onics® product line designed for continuous flexing applications in harsh environments. The cable featured an aramid fiber braid embedded into the jacket to add 1,800 lbs tensile strength as well as tinned copper conductors to lengthen flex life. Thermoplastic elastomer (TPE) insulation was incorporated, allowing the conductors to glide independently and thus preventing binding and corkscrewing. In addition, a polyurethane jacket served as the superior first line of defense by providing heavy-duty abrasion and cut resistance.

Checking in on the application 32 months after installation, it was determined that the custom bolster cable still had not yet required repair or replacement. The total cost for product & labor to implement the solution amounted to just $5,145, saving the customer $7,622 and allowing the plant to increase production time by 37 hours.