A large, well-known U.S. coal mining operation in the Midwest was experiencing weld cable failures due to the rough and rocky landscape of the site. Their current mining cable was exposed to abrasion, direct impact from being run over, exposure to oil, and weld splatter — from welding itself. All of these variables meant the customer was risking MSHA citations, which can add up quickly.

One of our field specialists carefully assessed the situation and considered all the types of damage this specific area was exposed to. From high temperatures to chemicals to abrasion to impact and chunking, these were quite the challenging circumstances. That’s when ATPC’s Super-Trex® 600V Welding Cable was introduced.

Key specs include:

| Features | Why It Matters in Mining |

|---|---|

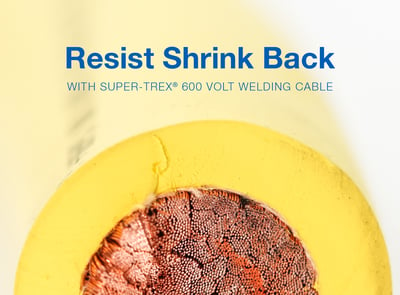

| Security-yellow TSE jacket | Highly visible; resists abrasion, oil, chemicals, impact — stands up to rough terrain |

| 25% thicker jacket wall | Extra protection vs. standard cable—less splitting, fewer cable failures |

| 100% fabric serve (jacket impregnated) | Improved flame, heat, and tear resistance—holds up around weld points. Reduces shrink back. |

| MSHA approval, flame & heat ratings | Meets regulatory and safety requirements; fewer risks of citations or shutdowns |

By switching from a commodity cable to a rugged ATPC high-temperature, abrasion-resistant cable, this customer successfully achieved an increase in production by 294 hours and a cost savings of $21,465 over a 22-month period.

Handles high heat, impact, and abrasion in one cable (fewer failure modes)

Visible, rugged jacket helps prevent accidental damage

Compliant with mining safety regs so you don’t incur fines or risk shutdowns

Long life means lower total cost of ownership (replacement, labor, interruptions)

Get in touch with an Amphenol TPC technical specialist today. We’ll assess your environment and quote a solution built for your toughest jobs.