One of the world’s leading makers of tissue, pulp, paper, packaging, and building products was frustrated by the need to replace soot blower cables every 2-3 days on 2 units at its flagship paper mill due to unacceptable wear and tear of the OEM product. The corrosive environment routinely destroyed the rubber jacketing of the cable. In addition, the cable was so heavy that it quickly sawed through itself due to continuous movement against the guide wire. For each instance of failure, the cost to replace the cable was $404 in parts and labor plus 3 hours of downtime — leading to extraordinarily high and unnecessary costs, not to mention hassle, every few days.

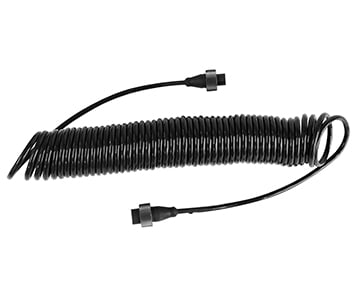

The TPC representative suggested Trex-Onics® Sootblower Cable for the long retractable soot blower application. Compatible with Diamond Power, Clyde Bergemann, and BEI blowers, TPC’s product is uniquely designed as a lightweight and abrasion, heat, and moisture-resistant retractile cable with an operating temperature range of -40°C to 105°C. Molded plugs offer a secure, easy-to-install connection and protect against the environment. The material is 30% lighter than the OEM cable, resulting in a smaller, tighter coil that is easier to manage and which simplifies installation. The ultra-smooth jacket resists abrasion as it slides gently along the soot blower guide wire.

After a 24-month period, it was confirmed by the customer that TPC’s Trex-Onics® Sootblower Cable had yet to fail, never requiring repair or replacement for an entire two years and counting! The customer’s total expense for the solution was $1,066 in products and labor, which means TPC’s solution saved the customer an astonishing $145,765 and allowed the mill to increase production by 1,086 hours over the course of two years!

An additional benefit was found with inventory control — Whereas OEM coil cords are often sold as “left-hand” or “right-hand” versions, Trex-Onics® Sootblower Cable fits either orientation, creating an ambidextrous solution that leaves just one part number to be managed. Soon after discovering these results at its primary paper mill, the company rolled out a company-wide recommendation that TPC’s product be used in all of its mills as a superior replacement for the OEM product.