Wastewater Treatment Plants can have sedimentation basins designed to collect runoff water to allow solids removed in runoff water to settle out. Construction of these basins has become a management practice to help control erosion and environmental degradation. These sedimentation basins can use up to tens of thousands of feet of cable and conduit, making using the right cable and inventory/delivery crucial.

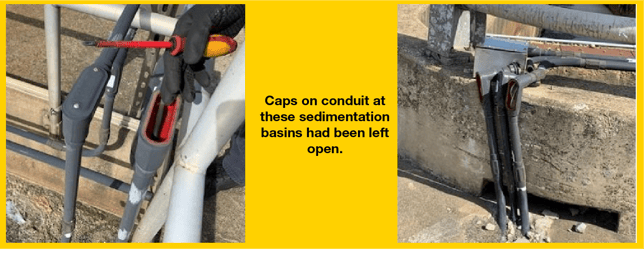

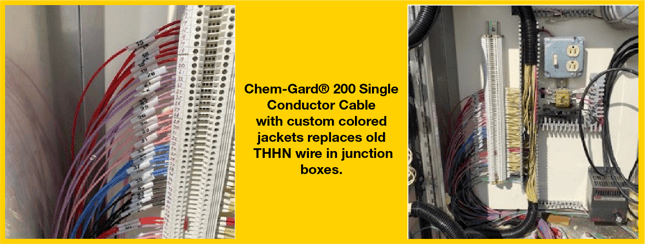

One of the world’s largest wastewater treatment plants was facing cable failure in their cable running through conduit under sedimentation basins. Caps on conduit at these sedimentation basins had been left open, so the old THHN wire was getting damaged and failing as a result of being run over or water infiltrating the conduit. The wastewater treatment plant was also facing cable failure in its junction boxes due to high temperatures.

One of our field specialists carefully assessed the situation and suggested using Chem-Gard® 200 Single Conductor Cable in conduit applications for the ease of pulling it through the conduit and in their junction boxes for its max conductor temperature of 200°C.

By switching to Chem-Gard, they were able to eliminate unwanted cable failures and eliminate costly downtime. Our Chem-Gard 200 did not fail even with open caps. The water treatment plant customer loved the performance and peace of mind that our Chem-Gard products provided to offer worry-free maintenance.