Choosing the right cable and proper installation of that cable is essential to having a long-lasting high performing electrical application. With a multitude of cables available for industrial markets, selecting the right one can be an overwhelming task.

By selecting high-quality, high-performance wire and cable products you can avoid downtime and constant replacement from damage or wear and keep your equipment and operation running. Follow these seven simple tips for a successful cable selection and installation.

Tips to consider when selecting cable:

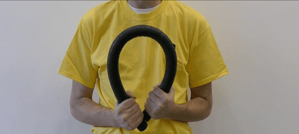

1. Know the Bend RadiusMake sure the bend radius meets the minimum requirements based on the cable design and application. A tighter bend radius will prematurely weaken conductors and lead to failure. A typical factor to determine a cable’s minimum bend radius is to multiply the cable’s Outside Diameter (O.D.) by 8.

Example: cable O.D. = .36” We multiply .36” x 8 = 2.9” In this example, we would expect the cable carrier to have a bend radius of 2.9” or larger to ensure optimal flex-life of the electrical cable.

Assuming an application has a fixed radius, we recommend using the smallest cable O.D. that you can. A smaller O.D. reduces mechanical stress on the conductors, allows for more spacing, better cooling and tighter turns.

2. Flex Life vs Flexibility

Flex life and flexibility are not the same. Flexibility is a measure of how easily, and how much movement a cable can endure. Flex life deals with a cable’s ability to withstand continuous flexing motion in an application without sustaining damage. Flex life is determined by cyclic bending or twisting under load. Cable may be very flexible but if not designed properly for the application, it may have a very short flex life

3. EnvironmentsAlong with the application, you should consider what type of environment it will live in and the type of abuse it will be subjected to. This includes abuse from abrasion or impact, exposure to extreme hot and/or cold environments, or contact with chemicals that may react negatively with cable materials. If the application requires dynamic flexing of the cable, what type of movement is involved; torsional/twisting motion, or linear motion as in a power-chain or cable-carrier application. Knowing and understanding the application and environment of the installation is key to selecting a cable that will perform up to expectations.

Every circumstance is different, which is why electrical cable selection is so essential. When in doubt, rely on the help of a trained expert to make a cable selection. It is helpful to have certain information such as the above ready before you speak with a cable representative. This will help your service provider better determine the best product for your application.

Tips to consider when installing cable:

4. Cable Movement

Do not restrict cable movement within an application with cable ties or clamps. This constricts the inner conductors and can cause the cable to fail.

5. Strain Relief

Always use some type of strain relief such as Grip-Seals cable glands or Kord Gard mesh cord grips at termination. This ensures the integrity of your cable assembly.

6. Jacketing

Always use a cable with a reinforced jacket in a reeling or pendant application.

7. Release Cable Tension

Before installation, allow the cable to hang for at least 24 hours. This releases any tension that exists from being stored on the reel.

Combining these seven tips with specific product lines of cable to address additional factors like extreme temperatures, abrasion, tension, impact, or chemicals will guide you to the best cable solution.

Let our team of experts lead you through choosing the right cable for your application. TPC works closely with our customers to provide specific wire and cable solutions, including custom-designed wire and cable products and in-house engineering expertise. We can tackle your toughest application challenges to create a customized solution perfect for your application. Contact a TPC representative today to help make the right cable and wire selection for the job.