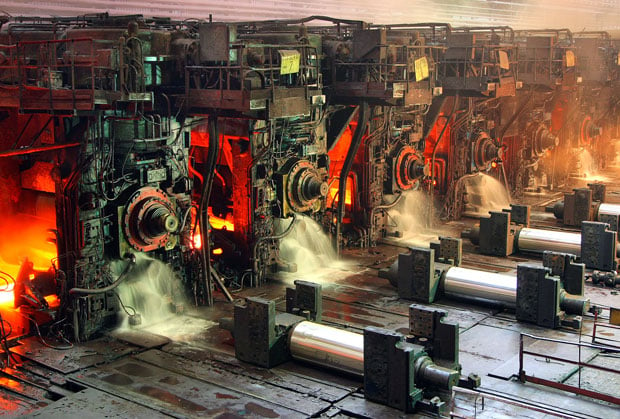

The steel market has faced many challenges such as supply chain issues and project halts due to the worldwide pandemic trials throughout recent years. Don’t let cable failure add to the mix!

Do you find yourself repairing your equipment’s cable and wire due to exposure to high temperatures, harsh chemicals, abrasion, or impact? What about difficulty handling or managing cables due to their weight, stiffness, or flexibility in tight spaces?

Stop the constant replacement of commodity-grade cables in your steel yard and switch to the secure investment of industrial cables and accessories to reduce downtime and increase the lifespan of your cables.

Why High-Temperature Industrial Cables?

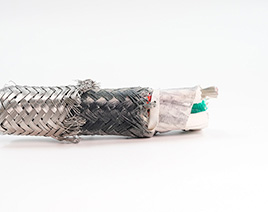

High-Temperature cables are typically made with high-quality materials and have advanced features such as specially woven glass-braid jackets impregnated with abrasion-resistant finishing compounds, silicone insulation, nickel-plated copper conductors, no-wick fillers, and available stainless steel overbraiding. These cables will have industry ratings and high-performance characteristics to ensure durability against the harsh environments your equipment faces.

High-Temperature cables are typically made with high-quality materials and have advanced features such as specially woven glass-braid jackets impregnated with abrasion-resistant finishing compounds, silicone insulation, nickel-plated copper conductors, no-wick fillers, and available stainless steel overbraiding. These cables will have industry ratings and high-performance characteristics to ensure durability against the harsh environments your equipment faces.

High-Temperature Wire and Cable Accessories

Consider completing your protection with accessories such as sleeving and cable tape.

High-Temperature Sleeves

High-Temperature Sleeves

Ceramic, silica, fiberglass, silicone and abrasion-resistant sleeves offer exceptional protection to give you peace of mind and the confidence that your cables and cords are strong enough to resist damage from flame, heat, molten splash, chemicals or other destructive forces.

Cable Tape

Cable Tape

A vulcanizing insulated wrap that doesn’t rely on adhesives to resist oil, water and other grime or a high-temperature silica tape will protect against radiant heat and flame.

Consider high-temperature industrial electrical cables and accessories inside these areas:

|

Area |

Applications |

|

Steel Production |

Crane Controls, Battery Chargers, Emergency Power, Cranes, Lathes |

|

Cold Mill |

Motor Leads |

|

Foundry |

Disa Sand, Mold Machine, Crane, Control Systems |

|

BOP = Basic Oxygen Process OR BOF = Basic Oxygen Furnace |

Transfer Car, Slag Pot Car, Precipitator & Bag House, Magnet Crane, Charge Crane, Power Along Furnace/Ladle Cars, Table Welders |

|

Blast Furnace |

Cranes, Transfer Cars, Reel Systems, Fluid Power Controllers, Mag Ladles, Pendant Control, Trippers, Port Welders, Switches, Mud Guns, Bottle Car Motor |

|

Caster |

Cranes, Cable Carriers, Tables, Welding Units, Motor Drives, Torch Burners, Motor Leads, Load Cell |

|

Crane |

Power & Control |

|

Electric Furnace

|

Furnace, Forge & Finishing, Motor Drives, Torque Car Power |

|

Hot Mill

|

Heat Treat, Cranes, Heat Controls, Pendant Control, Turtle Burners, Cable Protection, Extension Cord |

|

Integrated Steel

|

Power Tracks, Cranes, Welding Lead Stingers, Coke Ovens, Coke Pusher Guide Rack, Hood Hoists, Quench Pans |

Overall, high-temperature electrical industrial cables and accessories are essential in a steel mill as they provide a reliable and safe source of power and signal transmission, ensuring that the facility runs smoothly and efficiently.

TPC Wire & Cable is a leading supplier of rugged wire, cable, connectors, and assemblies engineered to perform in steel markets. View our products and read our case studies to see how we saved businesses time and money!