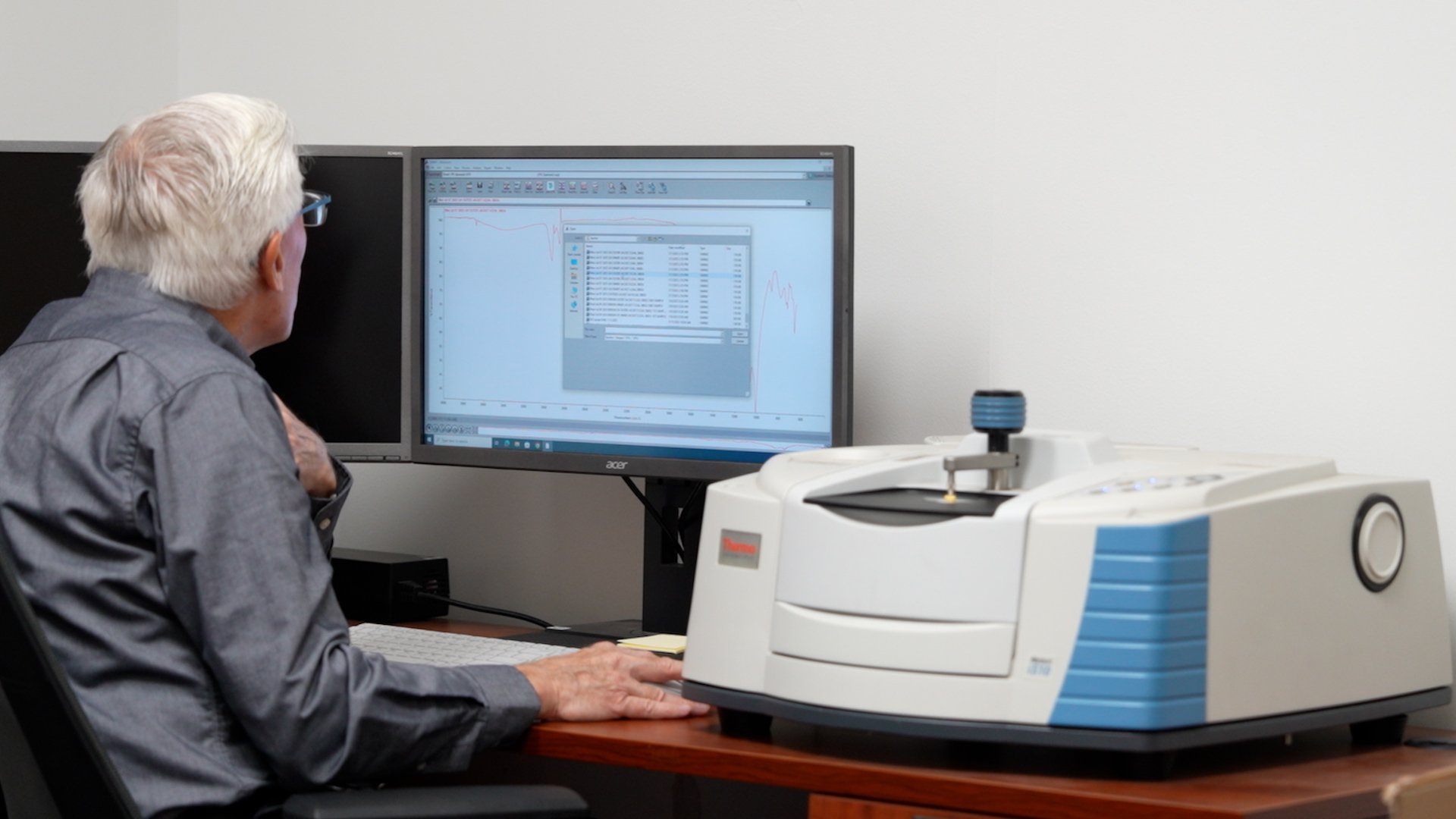

Understanding material composition is crucial in industrial cable manufacturing. Whether used for mining, aerospace, military, or chemical processing, cable materials must meet stringent requirements. That's why manufacturers rely on the FTIR Tester, a tool that uses infrared spectroscopy to identify and verify materials quickly and accurately.

An FTIR (Fourier Transform Infrared) Tester analyzes the molecular structure of materials to confirm their chemical makeup. This is essential for maintaining cable quality, ensuring compliance with industry standards, and avoiding costly product failures. This article explores how FTIR testing works, its importance, and how it supports cable performance in rugged environments.

What Is an FTIR Tester?

An FTIR Tester is a scientific instrument used to identify organic, polymeric, and some inorganic materials. It works by measuring how infrared light interacts with a sample's molecular bonds, producing a unique spectral fingerprint for each material.

How Does an FTIR Tester Work?

FTIR testers operate by:

- Directing infrared light at a sample

- Measuring absorbed wavelengths, which correspond to specific molecular vibrations

- Generating a spectrum, known as an IR fingerprint, that can be matched against a library of known materials

- Interpreting the results to determine the material’s identity, composition, or any potential contaminants

Watch our video

to see it in action and learn more from our ATPC Engineer.

Why Is FTIR Testing Important?

Material verification is non-negotiable in industries with strict performance and safety standards, such as mining, chemical processing, oil and gas, and aerospace. FTIR testing helps:

- Ensure material consistency for reliable cable performance

- Identify contaminants that could compromise durability or safety

- Confirm supplier quality and detect substitutions or mix-ups

- Comply with regulatory requirements and internal specifications

- Support failure analysis in the event of cable degradation

Applications of FTIR Testing in Rugged Industries

Manufacturing Quality Control

In manufacturing, FTIR testing is part of the QC process to verify incoming raw materials and finished cable products.

Failure Analysis

When cables fail in the field, FTIR testing can be used to compare a failed jacket or insulation sample to a known-good reference, helping to determine whether chemical degradation, contamination, or material substitution played a role.

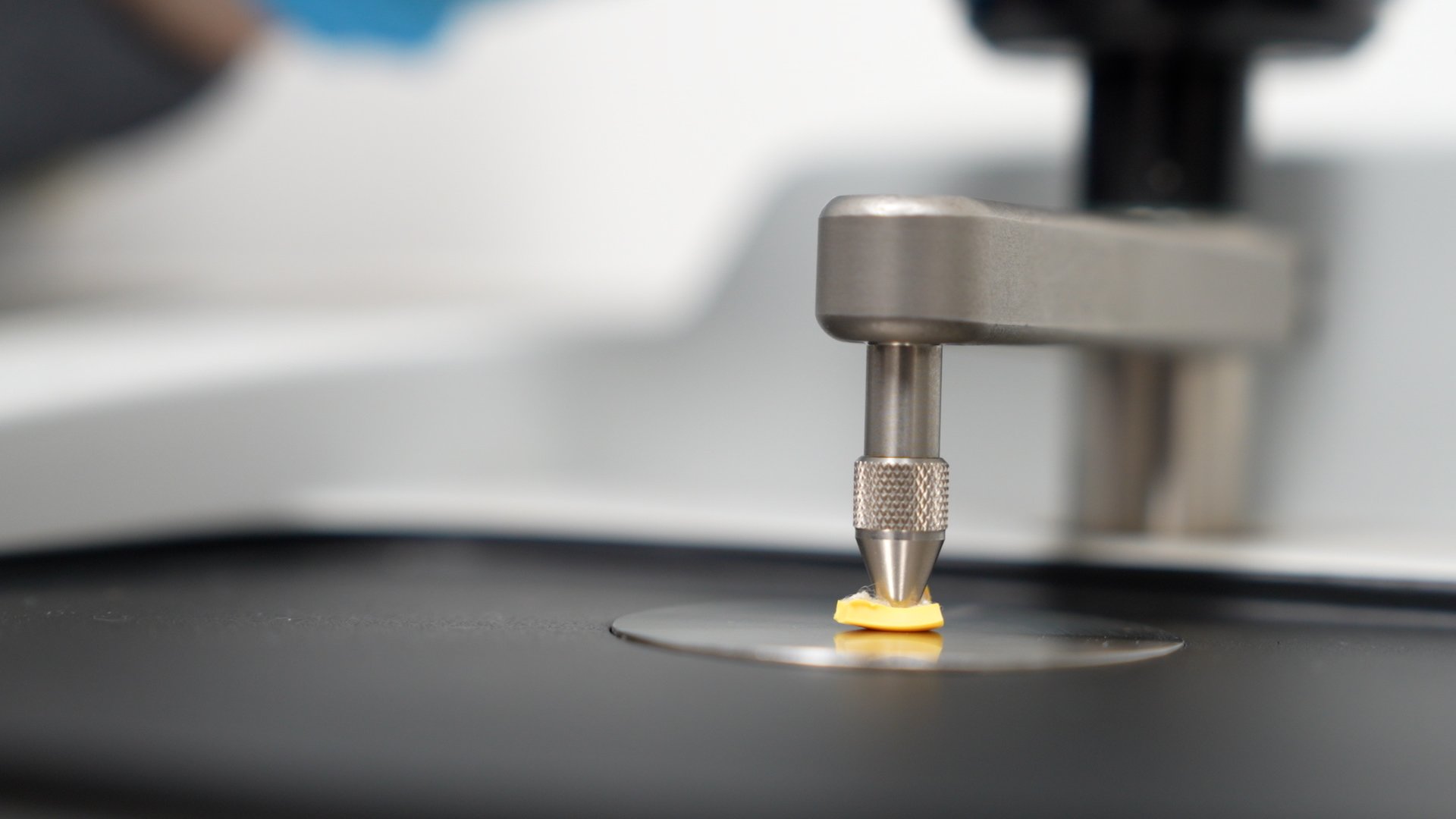

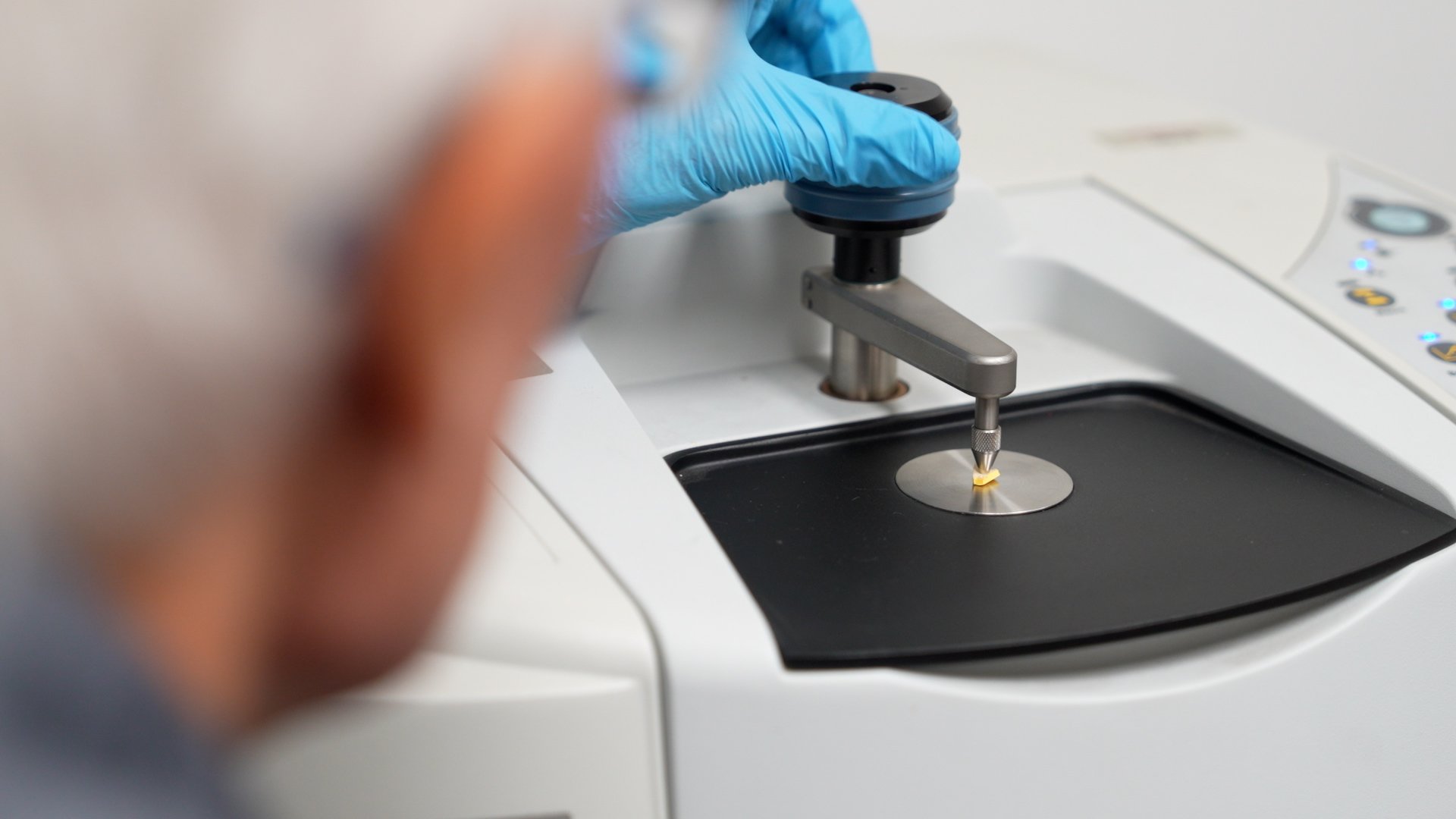

Attenuated Total Reflectance (ATR-FTIR) Method

ATR-FTIR is the most commonly used FTIR method in the cable industry—and for good reason. It allows direct surface analysis with minimal sample preparation, making it ideal for routine inspection and quick diagnostics.

Unlike traditional transmission FTIR methods that often require slicing or dissolving the material, ATR-FTIR uses a crystal (often diamond or germanium) to press against the cable jacket or insulation. Infrared light passes through the crystal and reflects internally, with a portion of the light penetrating just a few microns into the surface. This interaction provides a molecular fingerprint of the material without damaging the sample.

For cable applications, ATR-FTIR is particularly effective for:

- Identifying polymer types (e.g., PVC, TPE, XLPE, EPDM)

- Detecting contamination or degradation on outer jackets

- Verifying that raw materials and finished products meet spec

- Analyzing failed or worn cable components during service evaluations

Its speed, non-destructive nature, and ease of use make ATR-FTIR the go-to technique for both production labs and field support teams.

Factors Affecting FTIR Testing Accuracy

- Sample Preparation

Clean, consistent samples yield more accurate results. ATR-FTIR specifically requires a flat and smooth surface to ensure good contact with the crystal.

- Spectral Resolution

Higher resolution reveals more detail and distinguishes similar materials more accurately.

- Reference Libraries

Access to extensive, well-maintained spectral databases improves identification reliability—especially important for polymer-rich environments like cable production.

- Operator Skill

Trained technicians interpret spectra more accurately, especially in complex cases or when materials are mixed, aged, or degraded.

Choosing the Right FTIR Tester

When selecting an FTIR tester for cable applications, consider:

- Portability: Benchtop vs. handheld units for lab or field use

- Spectral Range: Ensure the device covers necessary IR regions for polymer analysis

- Library Support: Comprehensive and updatable libraries enhance material ID accuracy

- Software Usability: Intuitive software simplifies spectral analysis and reporting

- Speed and Sensitivity: Fast scan times and high sensitivity are critical for production environments

Best Practices for FTIR Testing in Cable Manufacturing

To maximize value from FTIR testing:

- Establish baseline material spectra for all cable products

- Perform incoming inspections on raw polymers

- Regularly verify material identity during production

- Document all results for traceability and audits

- Incorporate testing into failure investigations when performance issues arise

Conclusion

FTIR testing is a powerful tool for verifying the material quality of industrial cables. In environments where safety, compliance, and longevity are non-negotiable, knowing exactly what your cables are made of is essential.

ATR-FTIR stands out as the most efficient and reliable technique for the cable industry, enabling fast surface-level analysis with little to no sample prep. Whether you're validating incoming materials, resolving field failures, or ensuring product consistency, this method gives you the confidence that your cables are built to perform.

From mining to aerospace, FTIR testers help manufacturers ensure their cables can stand up to real-world demands. By investing in accurate FTIR analysis and integrating it into your quality control process, you gain confidence in every cable that leaves your facility—ready to perform in the harshest conditions.