If you work in the Shipyard or Marine Industry, you come face to face daily with the harsh conditions that wreak havoc on your operating equipment’s wire and cable. You constantly are struggling with environments causing premature cable failures. Shipyards are typically exposed to various factors that can damage cables, including moisture, extreme temperatures, corrosive materials, and heavy loads.

If you work in the Shipyard or Marine Industry, you come face to face daily with the harsh conditions that wreak havoc on your operating equipment’s wire and cable. You constantly are struggling with environments causing premature cable failures. Shipyards are typically exposed to various factors that can damage cables, including moisture, extreme temperatures, corrosive materials, and heavy loads.

A lot of activity is happening in the yard – from welding to building cable connections to running cable for both short-and long-term power. It's a lot when you’re on a tight schedule and must spend your valuable time on ship repairs and maintenance.

Here are Eight Industrial Wire and Cable products to prevent unwanted downtime in your shipyard.

- Molded Connector Assemblies

Molding creates an environment against dust, dirt, water and chemicals. Use a molded connector with a quick turn disconnect and a full 180˚ twist to lock into place, which improves upon the typical 3/4" turn used by commodity brands for mating.

Molding creates an environment against dust, dirt, water and chemicals. Use a molded connector with a quick turn disconnect and a full 180˚ twist to lock into place, which improves upon the typical 3/4" turn used by commodity brands for mating.

Shipyard Area: Power Supply, Tools & Machinery

Applications: Ship To Shore – Molded Locking Shore Power Assemblies

- Molded Locking Connector Assemblies

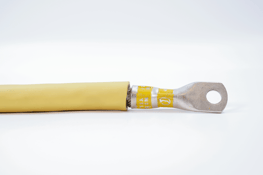

Avoid the time, hassle, and contamination associated with field-installable connections. TPC’s patented Molded Locking Connectors are compatible with THOF-E+ cable commonly selected by shipyards for resistance to impact, abrasion, and weather.

Shipyard Area: Power Supply

Applications: Generators

- Industrial Welding Cable

Rugged industrial welding cable prevents downtime caused by shrink-back and is built to perform and outlast any commodity cable in harsh environmental conditions. Not only will an industrial-grade welding cable prevent downtime, but it also allows for a safer welding environment. The abrasion/crushing resistance and jacketing that is flame resistant help to eliminate the exposure of copper that can cause arc strikes and shock hazards and will also aid in the safety of welding.

Rugged industrial welding cable prevents downtime caused by shrink-back and is built to perform and outlast any commodity cable in harsh environmental conditions. Not only will an industrial-grade welding cable prevent downtime, but it also allows for a safer welding environment. The abrasion/crushing resistance and jacketing that is flame resistant help to eliminate the exposure of copper that can cause arc strikes and shock hazards and will also aid in the safety of welding.Shipyard Area: Tools & Machinery

Applications: Welding Stingers / Whips, Welding Ground Leads, Welding Electrode Leads, Arc Welding

4. Weld Control Cable

The benefits of using an industrial-grade weld control cable include high durability and resistance to mechanical stresses, high flexibility and easy handling, reliable signal transmission, and easy installation and maintenance. Overall, the use of high-quality weld control cables can help to improve welding performance, increase efficiency, and reduce downtime and maintenance costs in your shipyard.

Shipyard Areas: Tools & Machinery

Applications: Welding Stingers / Whips, Welding Ground Leads, Welding Electrode Leads, Arc Welding

- Power Cable

Industrial power cables are critical in shipyards because they are designed to handle high voltage and harsh operating conditions that are common in shipyard environments. An industrial grade power cable will offer durability, safety, flexibility and are cost-effective- designed to operate reliably over an extended period.

Shipyard Areas: Power Supply

Applications: Ship to Shore – Molded Locking Shore Power Assemblies, Power Supply Applications, Bus Welding Boxes or Transformers, Generators

- Reeling Cable

Industrial grade reeling cables are designed to withstand repetitive bending, twisting, and pulling without suffering damage or degradation, which helps to ensure the reliable and safe operation of heavy machinery and electrical systems in shipyards. They are often constructed with high-quality materials such as copper conductors, robust insulation, and sturdy outer jackets to provide long-lasting performance in harsh environments.

Shipyard Areas: Dry Docks, Floating Docks, Berthing Stations, Travel Lifts, Piers

Applications: Cranes (Floating, Shore & Mobile)

- Festoon Cable

Industrial grade festoon cables in shipyards are critical to ensure the reliable and safe operation of heavy machinery and electrical systems in these environments. They are designed to withstand harsh environmental conditions and mechanical stresses that are commonly encountered in such environments. They are also constructed with materials that resist abrasion, impact, and chemical damage, which helps to prolong their lifespan and reduce maintenance costs.

Shipyard Area: Dry Docks, Floating Docks, Berthing Stations, Travel Lifts, Piers

Applications: Festoon Systems

- Custom Products

You might find yourself needing a custom wire, cable, or assembly that is designed for your specific application and environmental needs. Perhaps it’s a custom color cable to differentiate applications and minimize installation errors. Or custom labeling to mark ownership and deter theft. Ask about custom products and if they're the right fit for you.

You might find yourself needing a custom wire, cable, or assembly that is designed for your specific application and environmental needs. Perhaps it’s a custom color cable to differentiate applications and minimize installation errors. Or custom labeling to mark ownership and deter theft. Ask about custom products and if they're the right fit for you.

TPC Wire & Cable is a leading supplier of rugged wire, cable, connectors, and assemblies engineered to perform in harsh shipyard environments. Our flexible-yet-durable weld and shore power assemblies stand apart from all other products on the market in their ability to resist moisture, weather, and general hazards associated with shipyards. The result? Truly reusable shipyard cable products with an industry-leading life expectancy that saves time, labor, and overall cost of ownership while supporting safety initiatives. View our products and read case studies to see how we saved Shipyards time and money!