Welding cables face punishing conditions in high-demand welding and fabrication environments — heat, abrasion, chemicals, and constant motion. While wire size is important, many failures happen because the cable construction wasn’t matched to the application.

That’s why selecting the right welding cable means looking beyond just amperage. To prevent downtime and extend service life, you need to consider the full range of mechanical and environmental challenges your cables encounter every day.

Common Mechanical and Environmental Stressors that Shorten Cable Life

1. Abrasion and Impact

Dragging cables across rough floors or fabricated edges and accidental strikes from tools gradually wear down the jacket. Even a small breach allows contaminants inside, leading to corrosion or dielectric breakdown.

2. Heat and Hot Work Exposure

Cables routed near welding arcs or plasma cutting stations face radiant heat far above ambient conditions. General-purpose jackets like PVC soften or carbonize at temperatures well below those seen in fabrication.

3. Continuous Flexing and Torsion

Robotic welding arms and automated cutting tables subject cables to millions of flex cycles. Without fine-strand conductors and engineered insulation, copper work-hardens and fractures internally long before visible signs of failure.

4. Chemical and Oil Degradation

Hydraulic oils, cutting fluids, and solvents leach into jacket compounds, causing swelling or embrittlement. Over time, this compromises both strength and insulation.

Engineering Strategies to Extend Cable Life

Select Materials Matched to the Environment

-

For extreme abrasion, thermoset elastomer jackets (e.g., TSE) outperform thermoplastics by maintaining integrity even after repeated scuffing.

-

For chemical exposure, fluoropolymer-based jackets found in our Chem-Gard® line of products offer superior resistance to oils, acids, and solvents.

Design for Flex Life

-

Use fine-stranded, rope-lay conductors to distribute bending stress evenly.

-

Employ high-flex insulation systems that bond tightly to conductors to prevent corkscrewing or insulation creep.

Protect Against Heat

-

Use cables rated for continuous operation at or above the maximum expected ambient plus process-generated heat.

-

Apply heat shields or route cables outside high-radiant zones where possible.

Prevent Contamination Intrusion

-

Specify cables with tight jacket-to-core construction to prevent wicking.

-

Consider sealed or overmolded connectors to eliminate entry points for fluids.

Implement Controlled Routing and Strain Relief

-

Avoid pinch points, tight bend radii, and sharp edges along the cable path.

-

Install proper strain relief to transfer mechanical load away from termination points.

Proven Solutions for Welding & Fabrication Environments

For welding power applications, Amphenol TPC Wire & Cable offers two proven solutions designed to combat the exact failure modes common in fabrication shops:

Molded 12 Series® Weld Cable Assemblies – These assemblies feature a fully molded head that provides a 360° environmental seal, protecting terminations from moisture, oils, and abrasion. The robust strain relief prevents conductor breakage at the connection point, extending service life even under constant flex and movement.

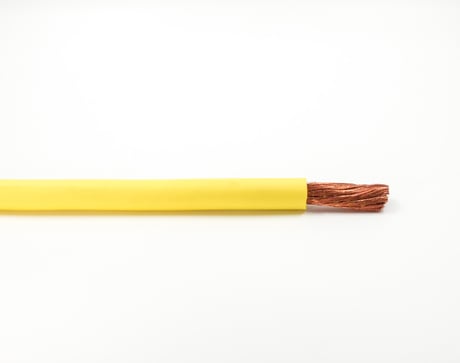

Super-Trex® 600 Volt Welding Cable – Engineered with a high strand count for maximum flexibility, this cable features a heavy-duty, extra-thick TSE jacket for exceptional abrasion and heat resistance. Its tight jacket-to-core construction helps prevent wicking of oil or contaminants, making it ideal for harsh, high-heat welding environments.

By specifying cables and assemblies built for the unique combination of mechanical, thermal, and chemical stresses found in fabrication work, you can significantly reduce downtime, lower maintenance costs, and improve safety.

Welding Cable Selection Checklist

When choosing a welding cable, ask these key questions

A. Select Cable Outer Jacket Material (Based on Environment)

✔️ Will it face abrasion, oils, or outdoor conditions?

B. Select Cable Flex Life

✔️ Will it be moved or coiled frequently?

C. Select Temperature Rating

✔️ Will it face extreme heat or subzero cold?

D. Sealing or Molding Option

✔️ Does it need molded ends to block moisture or chemicals?

E. Apply Wire Size

✔️ What amperage and cable length are required?

F. Routing & Strain Relief Accessories

✔️ How will the cable be routed, protected, and terminated?

Free Downloadable Guide

📥 Download the Welding Cable Selection Checklist (PDF)

Use this one-page tool during purchasing or maintenance planning to make sure every factor — not just wire size — is covered.

FAQs

Q: What is the best jacket material for welding cable?

A: Thermoset elastomer (TSE) jackets resist abrasion and heat better than PVC. For chemical resistance, fluoropolymer jackets like Chem-Gard® are recommended.

Q: How flexible should welding cable be?

A: If the cable is constantly moved, coiled, or used on welding reels, select extra-flexible cable with fine-stranded conductors. Static or fixed installations can use standard flex.

Q: Do I need molded connectors on welding cables?

A: Molded connectors provide a sealed, strain-relieved termination that resists oil, moisture, and abrasion — ideal for rugged, high-use environments.

Q: How do I know if my welding cable is failing?

A: Signs include visible jacket cuts, stiffness, exposed copper strands, overheating during use, or intermittent connection issues at the ends.

Key Takeaway

The right welding cable does more than carry current. By selecting jackets, flex ratings, temperature resistance, and terminations matched to your environment, you reduce downtime, improve safety, and lower total cost of ownership.

👉 Next step: View our welding cable size chart to select the correct wire gauge (AWG) for your amperage and cable length.