TPC Team

Our team of highly skilled people collaborates with customers to optimize their operations through quality products and innovative thinking. We are a group of engineered cable innovators, powering customer performance worldwide.

Not all wire and cable are created equally, with only a small elite group of solutions designed to withstand aggressive routine and harsh abuse. With the high price tag associated with electrical failures due to downtime and constant cord and cable replacement, it’s important to take a close look in the areas where cables are replaced most often.

Read More

Topics:

Application Sharing,

Reducing Downtime,

Environments,

Engineering

Can you think of at least one area where you’re replacing electrical wires and cables often?

Read More

Topics:

Automotive,

Manufacturing,

Food & Beverage,

Mining,

Wood, Paper, Pulp,

Steel,

Chemical,

Oil & Gas,

Transportation

You don't have time for downtime. As an industrial manufacturer, you are tasked with pushing your production equipment to capacity while simultaneously trying to reduce downtime. Maintenance management and service are essential for your plant to operate at the highest level possible while continuing to optimize efficiencies.

Read More

Topics:

Maintenance,

Reducing Downtime

When unexpected downtime occurs because of a lack of proper tools and accessories, the result can be both frustrating and costly. Electrical maintenance professionals need the right industrial grade cable tools and accessories to get the job done safely, accurately, and efficiently while simplifying repairs and replacements.

Having the right tools readily available for wire and cable maintenance needs can make a big difference in scheduled and unscheduled repairs.To reduce downtime and get the best use out of each tool, there are some key properties

for electrical maintenance professionals to consider.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products

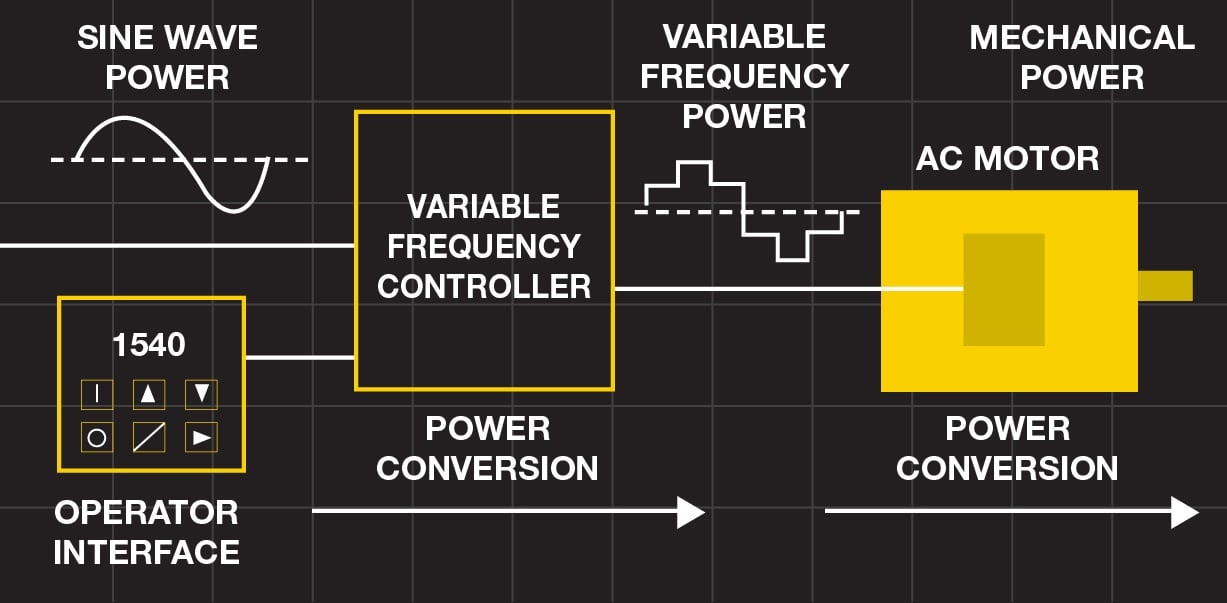

A variable frequency drive (VFD) is a type of controller that varies the frequency of the signal and voltage to control motor speed. Other common names for VFD include variable speed drive, adjustable speed drive, constant torque drive, inverter drive, and pulse width modulation (PWM) drive.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products,

Direct Current,

Alternating Current

Electric wire and cable systems are the lifeline of any industrial application. If one of your cables fail — the entire system comes to a halt, leaving you with costly downtime.

Read More

Topics:

Maintenance,

Reducing Downtime,

Products

As you know, the medium voltage cable business is full of risk if not carefully handled. When working within a 5kV to 35kV medium voltage range, it’s easy to keep your schedule top of mind, but safety has to come first. Do you have a deployment strategy? How does it perform for you?

Many companies talk about how safety is their top priority and promote the extra precautions they are taking to ensure personnel safety, but all too often, we hear of recordable injuries that could have been prevented by taking a few extra steps.

Think about these five considerations when choosing how to deploy your medium voltage power cables:

Read More

Topics:

Temporary Power,

Utility Industry,

Medium Voltage Cable

Flexible wire and cable is beneficial across various industrial applications from crane hoists to conveyors. It’s important to understand that this flexibility doesn't happen by accident. It’s achieved by maximizing best practices and using high-quality materials throughout each and every wire and cable product.

Read More

Topics:

Wire and Cable Tips,

Environments

It’s no secret that the shipyard industry is full of harsh conditions that threaten the operational life of traditional electrical wire and cable.

Read More

Topics:

Shipyard,

Shipbuilding,

Ship repair,

Ship maintenance

The Variable Frequency Drive (VFD) market is positioned for growth with some reports predicting a market value greater than $20 billion by 2021. What's driving this growth? Advantages to using VFD such as tighter process control and cost savings achieved through improved efficiency, reduced energy usage, and decreased maintenance. While controllers and motors combine as the two primary components to VFD, there is one additional component that is often overlooked and yet it is key to achieving the above-outlined benefits: the cable.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products,

Direct Current,

Alternating Current,

Variable Frequency Drive,

VFD

In an industrial setting, it’s imperative to be aware of the chemicals coming into contact with your cable and how they may impact the life of the cable. The cable’s jacket can swell, bloat, or harden after exposure, and even penetrate to the cable itself. Being armed with this knowledge will help you choose a proper cable that will last.

Here are some of the common chemicals to which your industrial power cables may be subjected.

Read More

Topics:

Environments,

Food & Beverage,

Chem-Gard,

Wood, Paper, Pulp

WHY HAVE AN EMERGENCY OPERATIONS PLAN?

If we've learned anything from recent events, having an operations plan in case of an emergency plays a very important role in keeping your facility up and running and your people safe. Your plan can provide guidance to employees during an emergency and highlight potential issues in your facility, such as hazardous conditions and a lack of resources, that you may be able to fix prior to an emergency happening.

Read More

Topics:

Temporary Power,

Environments,

Disaster Preparedness

The Wood, Pulp & Paper industry is known for producing wood chips, pulp slush, and waste water (aeration ponds). The paper-making process results in a lot dust and other particles that can put machinery and cables at an increased risk for failure.

Without proper maintenance, it is hard to protect your investments. Here are 5 maintenance tips for wood and pulp equipment:

Read More

Topics:

Maintenance,

Environments,

Products,

Wood, Paper, Pulp

Choosing the right reeling cable for your crane application can feel like a game of chance. You’re not sure which one will do the trick so, with blindfold on and fingers crossed, you choose a cable, install it on the application, and hope for a win. If this particular game of chance sounds risky & reckless to you, you're in good company. Check out our handy-dandy guide for matching the right reeling cable to your crane application - simply scroll for the low-res embedded images or click to download the high-res .pdf. Then, read on to solve your biggest challenge related to a more elusive type of reeling cable.

Read More

Topics:

Wire and Cable Tips,

Environments,

Products

STAY ON TOP OF INCREASING DEMANDS IN THE FOOD & BEVERAGE INDUSTRY

Electrical cables in the food and beverage industry are constantly exposed to a variety of abusive environments, such as constant washdowns, harsh chemicals, abrasion, heat, cold, flexing, constant motion and impact.

Read More

Topics:

Products,

Manufacturing,

Food & Beverage,

Connectors