Un variador de frecuencia (VFD) es un tipo de controlador que varía la frecuencia de la señal y el voltaje para controlar la velocidad del motor. Otros nombres comunes para el VFD incluyen variador de velocidad, controlador de velocidad ajustable, variador de par constante, controlador de inversor y controlador de modulación por ancho de pulso (PWM).

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products,

Direct Current,

Alternating Current

Very few industries like the Food and Beverage Industry involve complex and challenging hygienic requirements. Over time, high-pressure sprays, high temperature water, cleaners, and sanitizers can breakdown electrical cables and connectors. These harsh conditions result in frequent maintenance and cable failures which can cause unwanted downtime and slower production. It's important for businesses in the food and beverage industry to work with reputable suppliers or manufacturers who specialize in providing industrial wire and cable solutions that meet the industry's specific requirements and regulations.

Read More

Topics:

Maintenance,

Reducing Downtime,

Wire and Cable Tips,

Food & Beverage,

Connectors,

Chem-Gard,

Chemical,

High Temperature

Welding is important in the shipbuilding process because it can create joints that are water and oil-tight. As you can imagine, a strong weld is essential to the integrity of the ship. On one large ship, it can have hundreds of joints that require welding.

Shipbuilders face many challenges in the shipyard that could prevent progress and create downtime during operation. The need for durable equipment and an experienced welder that can address the demands of different applications is vital. Gaining the best results is all about having the right equipment and right person for the job, so it’s important to assess the application and choose your equipment and professional accordingly.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products,

Shipyard,

Shipbuilding,

Welding,

Welding Cable,

Welding Safety,

Weld Cable

It's officially winter, and if you live in a region similar to Ohio, there's no way to avoid it — no matter how much we may try. Right now, you're likely battling low temperatures, snow, freezing rain and ice. Perhaps you operate in a warmer region but your plant runs applications that are frigid in nature. We're talking to you, too!

Whether you're the former or the latter, freezing conditions require you to take additional steps to prepare your facility. Keep your plant operational by focusing on these three key areas.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products

Many of today's heating and processing applications are powered by steam and hot water. The technology used for generating heat or process energy is called a boiler. As you may already know, boilers can be both a highly efficient and cost-effective solution for generating energy. One way to keep your boiler running efficiently is to make sure it is kept clean.

Read More

Topics:

Application Sharing,

Maintenance,

TPC Wire & Cable,

Products,

Sootblower

What is a Total Cost of Ownership?

A total cost of ownership (TCO) is the purchase price of a product plus the cost of operations. When calculating the total cost of ownership, it exemplifies the overall value of a product over time giving you a better idea of how much something is worth.

When gathering data to make a purchasing decision, buyers should not only consider the initial price of a product, but they should also consider the long-term price of a product which would be the TCO. The item with the lower total cost of ownership is the better value overall.

Read More

Topics:

Maintenance,

Reducing Downtime,

Wire and Cable Tips,

Manufacturing,

Preventive Maintenance,

TCO,

CVA,

Cost Reduction

In the mining industry exposure to abrasion, impact, vibration, and tension are common causes for cable failure. Choosing a high quality, high performance mining cable, assembly, or accessory is critical. TPC can provide tough, Mine Safety and Health Administration (MSHA)-approved products suited for the mining industry that you need in order to get the job done right.

Read More

Topics:

Maintenance,

Reducing Downtime,

Custom Cable,

Mining

Electrical tape is a common household item that can be used for more than simply insulating electrical wires. The wide variety of uses and applications requires a product that can withstand a wide range of environments. Unfortunately, the simplicity of electrical tape can fall short in industrial applications. Electrical tape relies on adhesive and adhesive fails in dirty, oily and high temperature conditions. Regular electrical tape is also thin which requires substantially more tape in order to get any level of dielectric strength or abrasion protection. The quality of tape can mean be difference between a safe fix and a severe problem.

Read More

Topics:

Maintenance,

Environments,

Products,

Safety,

Oil & Gas,

Ship maintenance

You don't have time for downtime. As an industrial manufacturer, you are tasked with pushing your production equipment to capacity while simultaneously trying to reduce downtime. Maintenance management and service are essential for your plant to operate at the highest level possible while continuing to optimize efficiencies.

Read More

Topics:

Maintenance,

Reducing Downtime

When unexpected downtime occurs because of a lack of proper tools and accessories, the result can be both frustrating and costly. Electrical maintenance professionals need the right industrial grade cable tools and accessories to get the job done safely, accurately, and efficiently while simplifying repairs and replacements.

Having the right tools readily available for wire and cable maintenance needs can make a big difference in scheduled and unscheduled repairs.To reduce downtime and get the best use out of each tool, there are some key properties

for electrical maintenance professionals to consider.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products

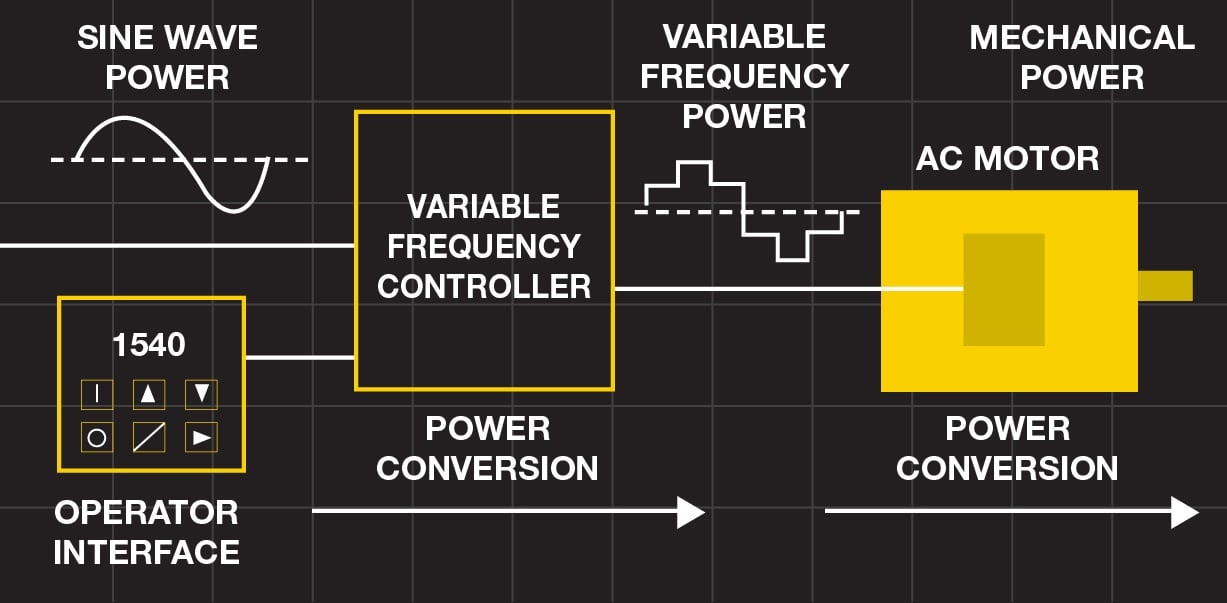

A variable frequency drive (VFD) is a type of controller that varies the frequency of the signal and voltage to control motor speed. Other common names for VFD include variable speed drive, adjustable speed drive, constant torque drive, inverter drive, and pulse width modulation (PWM) drive.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products,

Direct Current,

Alternating Current

Electric wire and cable systems are the lifeline of any industrial application. If one of your cables fail — the entire system comes to a halt, leaving you with costly downtime.

Read More

Topics:

Maintenance,

Reducing Downtime,

Products

The Variable Frequency Drive (VFD) market is positioned for growth with some reports predicting a market value greater than $20 billion by 2021. What's driving this growth? Advantages to using VFD such as tighter process control and cost savings achieved through improved efficiency, reduced energy usage, and decreased maintenance. While controllers and motors combine as the two primary components to VFD, there is one additional component that is often overlooked and yet it is key to achieving the above-outlined benefits: the cable.

Read More

Topics:

Maintenance,

Wire and Cable Tips,

Products,

Direct Current,

Alternating Current,

Variable Frequency Drive,

VFD

The Wood, Pulp & Paper industry is known for producing wood chips, pulp slush, and waste water (aeration ponds). The paper-making process results in a lot dust and other particles that can put machinery and cables at an increased risk for failure.

Without proper maintenance, it is hard to protect your investments. Here are 5 maintenance tips for wood and pulp equipment:

Read More

Topics:

Maintenance,

Environments,

Products,

Wood, Paper, Pulp