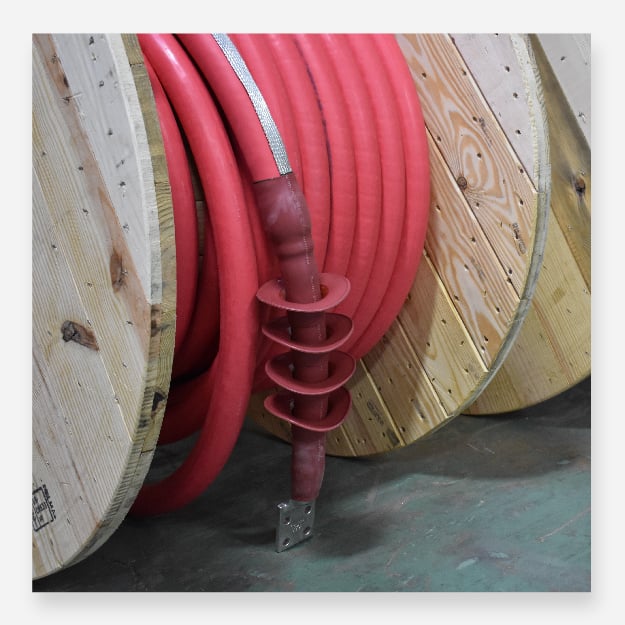

La resistencia a la tracción es una propiedad crítica que determina la capacidad de un cable para resistir la fuerza aplicada sin romperse. En aplicaciones industriales, como la minería, la automatización y el manejo de materiales, los cables para enrolladores experimentan tensiones constantes, flexión y estrés mecánico. Comprender la resistencia a la tracción ayuda a prevenir fallos prematuros, garantizando seguridad, confiabilidad y eficiencia en entornos exigentes.